Untuk mendapatkan informasi lebih lengkap tentang:

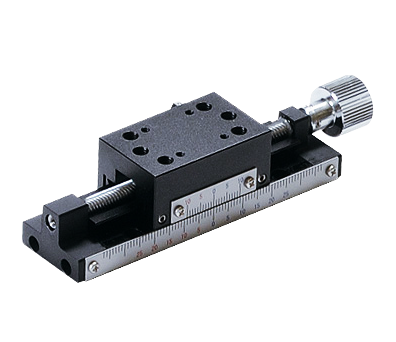

Miruc Dovetail Stage for Microscopy

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

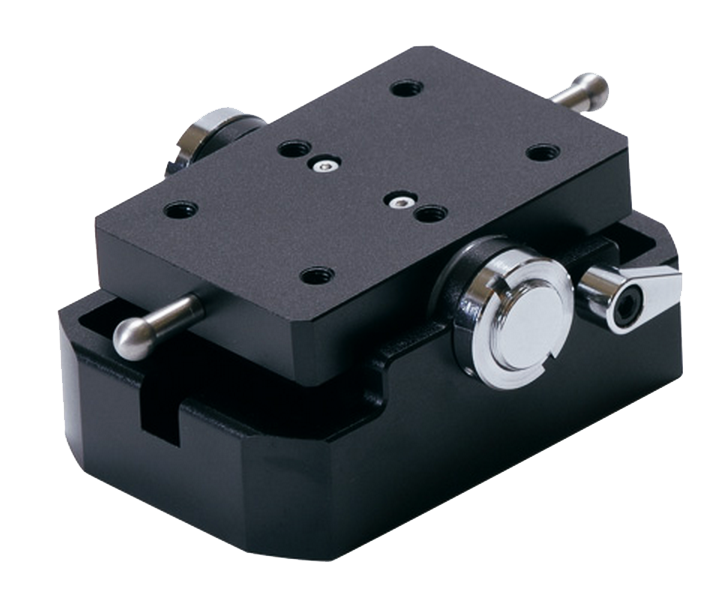

The Miruc's made in Japan dovetail stage is a sliding unit which could be used for a number of position settings, from the workplace to device mounting. Smooth sliding travels are created on each stages by the hands of their own craftsmanship, which is incomparable to any other stages in the market. Miruc’s stages can be used as a standard component and/or machine element parts for tooling, in a number of industrial fields.

These products are characterised by their smooth sliding action and high durability. Also, the use of a clamp lever allows secure holding force and flexibility in the positioning and direction of the lever. The bolt fixtures are coated with viscoelastic material that absorbs and reduces vibration and shock, and prevents screw loosening.

Features :

-

Over 10,000 combination of X,XY,XZ,YZ,XYZ axis fully applicable for any specimen observation

-

Each model number indicates function for convenient selection and application

-

Excellent for handling, to scale and hold the object can all be aligned in a single direction, interchangeable and precise movement

-

Equipped with double clamp allows for firn fixing strength.

-

Characterised by their smooth sliding action and high durability

Benefits :

-

As the Miruc dovetail stage can be combined in a rich variety of ways, the product range is collectively known as Multi Joint stages

-

Used as standard positioning component in FA and other industrial fields

-

Used as machine element part of tooling

SPESIFIKASI Miruc Dovetail Stage for Microscopy

Miruc Dovetail Stage

| Model | Stage surface (mm) | Degree of movement (mm) | Degree of movement per handle rotation (mm) | Movement precision (μm) | Load bearing N (kgf) | Minimum scale reading (mm) | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|

| Straightness | Degree of parallelism during operation | |||||||

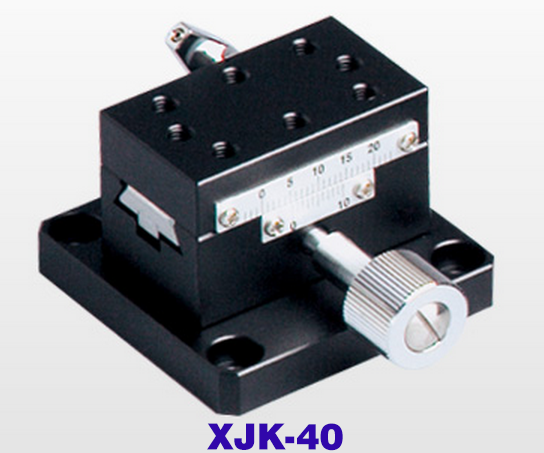

| XJK-40 | 24.8 x 42 | ± 12 | 18 | 20 | 25 | 29.4 (3) | 0.1 | 0.17 |

| XJK-60 | 40 x 60 | ± 21 | 18 | 30 | 30 | 39.2 (4) | 0.1 | 0.29 |

| XJK-90 | 40 x 90 | ± 35 | 18 | 30 | 30 | 39.2 (4) | 0.1 | 0.40 |

| XJK-140 | 40 x 140 | ± 60 | 18 | 30 | 30 | 39.2 (4) | 0.1 | 0.56 |

| XLSR-100 | 25 x 42 | ± 40 | 18 | 30 | 30 | 29.4 (3) | 0.1 | 0.14 |

| XLSR-150 | 25 x 42 | ± 65 | 18 | 40 | 40 | 29.4 (3) | 0.1 | 0.17 |

| SK-60C/60R/60B/60Y *1 | 40 x 60 | ± 21 | 18 | 30 | 30 | 19.6 (2.0) | 0.1 | 0.11 |

| XTSC-70-2 *2 | 25 x 40 | ± 17 | 2 | 30 | 30 | 29.4 (3) | 0.1 | 0.12 |

| XTSC-70-5 *2 | 25 x 40 | ± 17 | 5 | 30 | 30 | 29.4 (3) | 0.1 | 0.12 |

| XTSC-90-2 *2 | 25 x 40 | ± 27 | 2 | 30 | 30 | 29.4 (3) | 0.1 | 0.14 |

| XTSC-90-5 *2 | 25 x 40 | ± 27 | 5 | 30 | 30 | 29.4 (3) | 0.1 | 0.14 |

| XTSC-90-10 *2 | 25 x 40 | ± 27 | 10 | 30 | 30 | 29.4 (3) | 0.1 | 0.14 |

| XTSC-120-2 *2 | 25 x 40 | ± 42 | 2 | 30 | 30 | 29.4 (3) | 0.1 | 0.16 |

| XTSC-120-5 *2 | 25 x 40 | ± 42 | 5 | 30 | 30 | 29.4 (3) | 0.1 | 0.16 |

| XTSC-120-10 *2 | 25 x 40 | ± 42 | 10 | 30 | 30 | 29.4 (3) | 0.1 | 0.16 |

| XTSC-150-5 *2 | 25 x 40 | ± 57 | 5 | 40 | 40 | 29.4 (3) | 0.1 | 0.18 |

| XTSC-150-10 *2 | 25 x 40 | ± 57 | 10 | 40 | 40 | 29.4 (3) | 0.1 | 0.18 |

| FR-X | 25 x 25 | ± 8 | 0.5 | 20 | 20 | 19.6 | 1.0 | 0.04 |

Miruc Dovetail Stage

| Model | Stage surface (mm) | Degree of movement (mm) | Degree of movement per handle rotation (mm) | Movement precision (μm) | Load bearing N (kgf) | Minimum scale reading (mm) | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|

| Straightness | Degree of parallelism during operation | |||||||

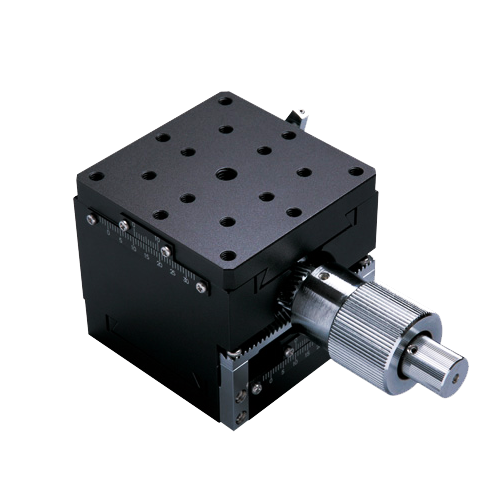

| XYJK-40 | 24.8 x 42 | ± 12 | 18 | 20 | 25 | 24.5 (2.5) | 0.1 | 0.29 |

| XYJK-60 | 40 x 60 | ± 21 | 18 | 30 | 30 | 34.3 (3.5) | 0.1 | 0.51 |

| XYJK-90 | 40 x 90 | ± 35 | 18 | 30 | 30 | 34.3 (3.5) | 0.1 | 0.73 |

| RVS-60 | 60 x 60 | ±12 | X-axis4.2 Y-axis18 | 30 | 30 | 39.2 (4) | 0.1 | 0.62 |

| FR-XY | 25x25 | ±8 | 0.5 | 20 | 20 | 14.7 | 1.0 | 0.08 |

Miruc Dovetail Stage

| Model | Stage surface (mm) | Degree of movement (mm) | Degree of movement per handle rotation (mm) | Movement precision (μm) | Load bearing N (kgf) | Minimum scale reading (mm) | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|

| Straightness | Degree of parallelism during operation | |||||||

| ZJK-40 *1 | 24.8 x 42 | ± 12 | 18 | 20 | 25 | 14.7 (1.5) | 0.1 | 0.17 |

| ZJK-60 *1 | 40 x 60 | ± 21 | 18 | 30 | 30 | 19.6 (2.0) | 0.1 | 0.33 |

| ZJK-90 *1 | 40 x 90 | ± 35 | 18 | 30 | 30 | 19.6 (2.0) | 0.1 | 0.45 |

| FR-Z | 25 x 25 | ± 8 | 0.5 | 20 | 20 | 9.8 | 1.0 | 0.04 |

| ZTSC-70-2 *2 | 25 x 40 | ± 17 | 2 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.16 |

| ZTSC-70-5 *2 | 25 x 40 | ± 17 | 5 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.16 |

| ZTSC-90-2 *2 | 25 x 40 | ± 27 | 2 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.18 |

| ZTSC-90-5 *2 | 25 x 40 | ± 27 | 5 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.18 |

| ZTSC-90-10 *2 | 25 x 40 | ± 27 | 10 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.18 |

| ZTSC-120-2 *2 | 25 x 40 | ± 42 | 2 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.20 |

| ZTSC-120-5 *2 | 25 x 40 | ± 42 | 5 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.20 |

| ZTSC-120-10 *2 | 25 x 40 | ± 42 | 10 | 30 | 30 | 14.7 (1.5) | 0.1 | 0.20 |

| ZTSC-150-5 *2 | 25 x 40 | ± 57 | 5 | 40 | 40 | 14.7 (1.5) | 0.1 | 0.22 |

| ZTSC-150-10 *2 | 25 x 40 | ± 57 | 10 | 40 | 40 | 14.7 (1.5) | 0.1 | 0.22 |

Miruc Gate turning stage

| Model | Stage surface (mm) | Degree of movement (°) | Load bearing N (kgf) | Minimum scale reading (°) | Weight (kg) |

|---|---|---|---|---|---|

| RC-60 | 60 x 60 | 180°bending 360°rotarion flexibility | 39.2 (4) | 1° | 0.5 |

| RC-90 | 90 x 90 | 180°bending 360°rotarion flexibility | 39.2 (4) | 1° | 0.57 |

* Material: stage body: aluminium alloy, surface treatment: matt black alumite

Miruc Rotational stage

| Model | Stage surface (mm) | Degree of movement (°) | Eccentricity (mm) | Load bearing N (kgf) | Minimum scale reading (°) | Weight (kg) |

|---|---|---|---|---|---|---|

| KTS-40 | φ 40 | 360° | 0.05 | 49.0 (5) | 2° | 0.06 |

| KTS-60 | φ 60 | 360° | 0.05 | 68.6 (7) | 1° | 0.2 |

* Material: stage body: aluminium alloy, surface treatment: matt black alumite

* Accessory screws M4 x 8 Hexagonal bolts - 4 SUSXM7

Miruc Thin XY rotational stage

| Model | Stage surface (mm) | Degree of movement (mm) | Degree of movement per handle rotation (mm) | Movement precision (μm) | Load bearing N (kgf) | Weight (kg) | |

|---|---|---|---|---|---|---|---|

| Straightness | Degree of parallelism during operation | ||||||

| XYR-60 | φ 60 | ± 21 360° | 4.2 | 30 | 30 | 34.3 (3.5) | 0.39 |

| XYR-90A | φ 90 | ± 35 360° | 4.2 | 30 | 30 | 34.3 (3.5) | 0.88 |

| XYR-90B | φ 90 | ± 35 360° | 4.2 | 30 | 30 | 34.3 (3.5) | 0.84 |

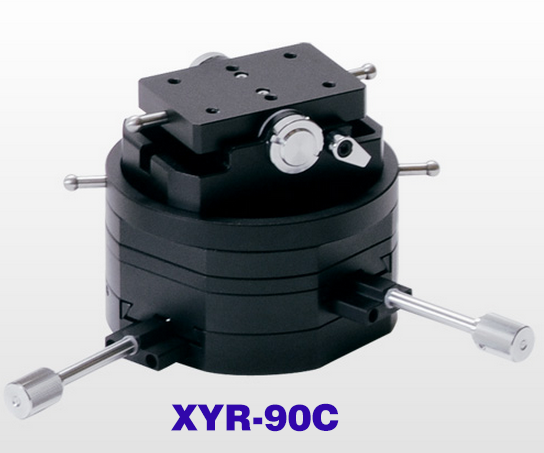

| XYR-90C | φ 90 | ± 35 360° ± 20° | 4.2 | 30 | 30 | 29.4 (3) | 1.03 |

*Material: stage body: aluminium alloy, surface treatment: matt black alumite

Miruc Tilt stage

| Model | Stage surface (mm) | Degree of movement (°) | Load bearing N (kgf) | Weight (kg) |

|---|---|---|---|---|

| AIC-60 | 40 x 60 | ± 20° | 29.4 (3) | 0.22 |

*Material: stage body: aluminium alloy, surface treatment: matt black alumite

Harga Miruc Dovetail Stage for Microscopy

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.