Untuk mendapatkan informasi lebih lengkap tentang:

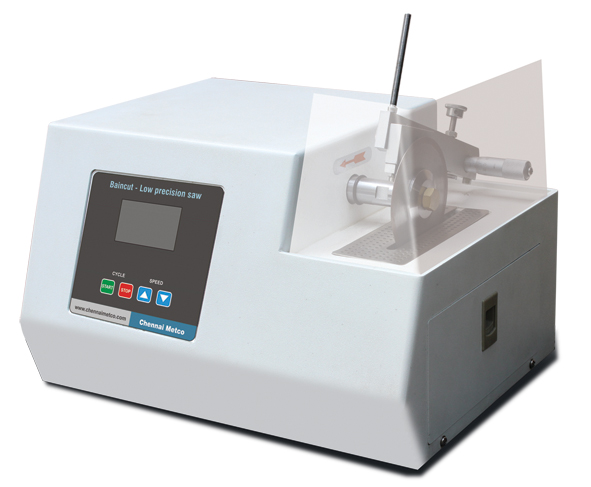

Chennai Metco Low Speed Saw Baincut - LSS

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Chennai Metco Baincut - LSS is a sturdy light cutter for metallographic sectioning of metals, fibres, plastic, ceramic and mineral samples with various level of toughness. Chennai Metco Baincut - LSS is suitable for cutting specimen of smaller workpiece from softer material with sturdy locking system. Application includes micro analysis built of ceramics coil, small mechatronics parts, locking screw, padlocks, fibres in ABS plastic, and many more.

Sectioning a specimen with appropriate method is the crucial step for studying the micro-structure of materials. Various surface of material with smaller sized such as: metals, fibres, plastic, ceramic and mineral samples with medium level of toughness can be examined conveninently. The aim is to get an excellent surface condition with minimal damage. Material sectioning should be done with abrasive cutter with minimal heat from frictions which may alter the microstructure and produce false metallographic characterization.

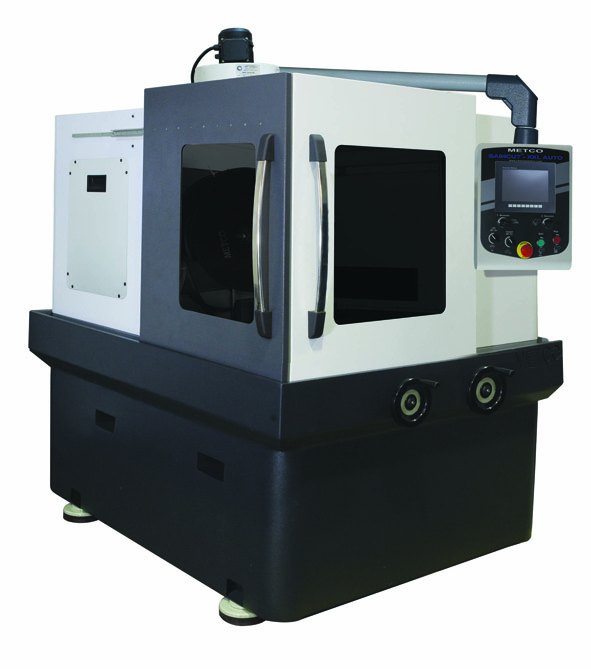

Your investment on Chennai Metco Low Speed Saw Baincut - LSS will allow you to work on sectioning various precision specimen of any workpiece. The slow speed cutter is mostly used for accurate sectioning of very small, hard components for R & D. Chennai Metco provides a complete solution for metallography and metallurgy inspection by various methods of grinding, polishing, and etching. For finer sample then the next step will be grinding and polish finer abrasive particles with BAINPOL VTD until the desired surface quality is ready and the metallographic structure of specimen can be observed and measured in detail with Vision engineering TIM5 or digital, optical, or electron microscopy.

Chennai Metco Low Speed Saw Baincut - LSS Features:

- Precision section saw designed for cutting all types of materials with ease.

- Cutting capacity upto 20 mm

- Continuously variable speed 0 - 600 RPM

- Single Phase AC motor 230 V / 50 Hz

- Down feed facility with different weights

- Arbor size-12.7mm

- Micrometer for cross-feed adjustment (0 - 25mm)

- Automatic cut-off switch

- Machine Size: 400mm x 300mm x 250mm

- Easy movable built-in coolant tray

SPESIFIKASI Chennai Metco Low Speed Saw Baincut - LSS

Chennai Metco Low Speed Saw Baincut - LSS Ordering Guide:

| Cutting capacity upto 20 mm |

| Continuously variable speed 0 - 600 RPM |

| Single Phase AC motor 230 V / 50 Hz |

| Down feed facility with different weights |

| Arbor size-12.7mm |

| Micrometer for cross-feed adjustment (0 - 25mm) |

| Automatic cut-off switch |

| Machine Size: 400mm x 300mm x 250mm |

| Easy movable built-in coolant tray |

Harga Chennai Metco Low Speed Saw Baincut - LSS

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.