Untuk mendapatkan informasi lebih lengkap tentang:

Chennai Metco Cold Cutting Baincut UM

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

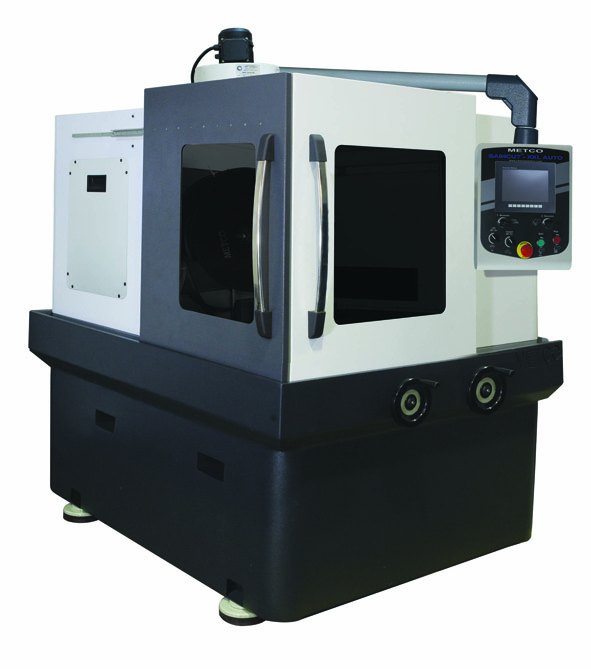

Chennai Metco BAINCUT-UM adalah pemotong model meja yang kokoh untuk persiapan metalografi dengan cara membagi-bagi sampel logam, keramik, dan mineral. Pemotong ini memiliki basis pengecoran paduan solid dengan sistem pendingin sirkulasi ulang. Hood FRP, jendela pengliatan, selang pembersih, dan kunci pengaman disertakan dalam pemotong serbaguna ini. Ruang besar di zona pemotongan menawarkan fleksibilitas untuk menggunakan berbagai jenis fixture. Aksi pemotongan dimungkinkan dengan menurunkan lengan (gerakan Z) dan pergerakan meja longitudinal melalui bidang pemotongan (gerakan Y). Opsi gerakan samping tambahan (gerakan X) adalah suatu keuntungan. Posisi roda gerakan Z yang terkunci menawarkan kenyamanan ekstra. Cocok untuk berbagai aplikasi termasuk roda gigi kecil, komponen otomotif berukuran sedang, dan poros. Memotong spesimen dengan metode yang tepat adalah langkah penting untuk mempelajari mikrostruktur bahan. Berbagai permukaan bahan dengan ukuran yang lebih kecil seperti logam, serat, plastik, keramik, dan sampel mineral dengan tingkat kekerasan yang berbeda-beda dapat diperiksa dengan mudah. Tujuannya adalah untuk mendapatkan kondisi permukaan yang sangat baik dengan kerusakan minimal. Pemotongan material harus dilakukan dengan pemotong abrasif dengan jumlah pendingin yang cukup untuk mencegah panas yang berlebihan dari gesekan yang dapat mengubah mikrostruktur dan menghasilkan karakterisasi metalografi yang salah. Investasi Anda di seri Chennai Metco Baincut UM akan memungkinkan Anda memiliki mesin pembagian dingin yang serbaguna untuk berbagai tujuan. 2 model tersedia; seri Baincut UM untuk operasi manual dan terjangkau, dan Baincut UM-AUto dengan kecepatan potong yang dapat diprogram dan mode operasi layar sentuh untuk hasil yang sangat dapat diprediksi. Selain itu, mesin ini juga dapat digunakan dengan fungsi sayatan pisau ganda, sehingga Anda dapat memotong bagian tengah setiap sampel. Untuk sampel yang lebih halus, langkah berikutnya adalah menggiling dan menggosok partikel abrasive yang lebih halus dengan BAINPOL VTD hingga kualitas permukaan yang diinginkan siap dan struktur metalografi sampel dapat diamati dan diukur secara detail dengan Vision Engineering TIM5 atau digital, optical, atau electron microscopy. Dengan Chennai Metco, menyediakan dukungan langsung untuk kualifikasi dan sertifikasi industri terkait inspeksi metalografi. Fitur Chennai Metco Cold Cutting Baincut UM: Pemotong model meja yang kokoh untuk memotong logam, keramik, dan sampel mineral Pondasi paduan padat dengan sistem pendingin sirkulasi untuk pemotong umum. Tersedia 2 model; seri UM untuk operasi manual dan UM-AUto dengan kecepatan potong yang dapat diprogram dan mode operasi layar sentuh. Kapasitas pemotongan hingga 80 mm Motor 5 HP, 3 Fase dengan kecepatan putaran 2800 rpm Diameter roda potong 12 " Anti percikan, tahan korosi dengan jendela transparan FRP, dengan selang pembersih, kunci pengaman disertakan Pendinginan dengan dua jet air aliran tinggi untuk memberikan pendinginan optimum Gerakan Y (pemotongan longitudinal) Saluran air pendingin besar 65mm Tangki pendingin resirkulasi bergerak dengan kapasitas 100 liter yang terpasang di dalam mesin Ada lubang kecil di dinding samping hood untuk memotong sampel yang lebih panjang Tempat T Slot: 260mm X 260 mm dengan slot T 8mm Ukuran Mesin: 850 X 1100 X 850 mm Ukuran Stand: 1060x900x850 mm

Chennai Metco BAINCUT-UM adalah pemotong model meja yang kokoh untuk persiapan metalografi dengan cara membagi-bagi sampel logam, keramik, dan mineral. Pemotong ini memiliki basis pengecoran paduan solid dengan sistem pendingin sirkulasi ulang. Hood FRP, jendela pengliatan, selang pembersih, dan kunci pengaman disertakan dalam pemotong serbaguna ini. Ruang besar di zona pemotongan menawarkan fleksibilitas untuk menggunakan berbagai jenis fixture. Aksi pemotongan dimungkinkan dengan menurunkan lengan (gerakan Z) dan pergerakan meja longitudinal melalui bidang pemotongan (gerakan Y). Opsi gerakan samping tambahan (gerakan X) adalah suatu keuntungan. Posisi roda gerakan Z yang terkunci menawarkan kenyamanan ekstra. Cocok untuk berbagai aplikasi termasuk roda gigi kecil, komponen otomotif berukuran sedang, dan poros.

Memotong spesimen dengan metode yang tepat adalah langkah penting untuk mempelajari mikrostruktur bahan. Berbagai permukaan bahan dengan ukuran yang lebih kecil seperti logam, serat, plastik, keramik, dan sampel mineral dengan tingkat kekerasan yang berbeda-beda dapat diperiksa dengan mudah. Tujuannya adalah untuk mendapatkan kondisi permukaan yang sangat baik dengan kerusakan minimal. Pemotongan material harus dilakukan dengan pemotong abrasif dengan jumlah pendingin yang cukup untuk mencegah panas yang berlebihan dari gesekan yang dapat mengubah mikrostruktur dan menghasilkan karakterisasi metalografi yang salah.

Investasi Anda di seri Chennai Metco Baincut UM akan memungkinkan Anda memiliki mesin pembagian dingin yang serbaguna untuk berbagai tujuan. 2 model tersedia; seri Baincut UM untuk operasi manual dan terjangkau, dan Baincut UM-AUto dengan kecepatan potong yang dapat diprogram dan mode operasi layar sentuh untuk hasil yang sangat dapat diprediksi. Selain itu, mesin ini juga dapat digunakan dengan fungsi sayatan pisau ganda, sehingga Anda dapat memotong bagian tengah setiap sampel. Untuk sampel yang lebih halus, langkah berikutnya adalah menggiling dan menggosok partikel abrasive yang lebih halus dengan BAINPOL VTD hingga kualitas permukaan yang diinginkan siap dan struktur metalografi sampel dapat diamati dan diukur secara detail dengan Vision Engineering TIM5 atau digital, optical, atau electron microscopy. Dengan Chennai Metco, menyediakan dukungan langsung untuk kualifikasi dan sertifikasi industri terkait inspeksi metalografi.

Fitur Chennai Metco Cold Cutting Baincut UM:

- Pemotong model meja yang kokoh untuk memotong logam, keramik, dan sampel mineral

- Pondasi paduan padat dengan sistem pendingin sirkulasi untuk pemotong umum.

- Tersedia 2 model; seri UM untuk operasi manual dan UM-AUto dengan kecepatan potong yang dapat diprogram dan mode operasi layar sentuh.

- Kapasitas pemotongan hingga 80 mm

- Motor 5 HP, 3 Fase dengan kecepatan putaran 2800 rpm

- Diameter roda potong 12 "

- Anti percikan, tahan korosi dengan jendela transparan FRP, dengan selang pembersih, kunci pengaman disertakan

- Pendinginan dengan dua jet air aliran tinggi untuk memberikan pendinginan optimum

- Gerakan Y (pemotongan longitudinal)

- Saluran air pendingin besar 65mm

- Tangki pendingin resirkulasi bergerak dengan kapasitas 100 liter yang terpasang di dalam mesin

- Ada lubang kecil di dinding samping hood untuk memotong sampel yang lebih panjang

- Tempat T Slot: 260mm X 260 mm dengan slot T 8mm

- Ukuran Mesin: 850 X 1100 X 850 mm

- Ukuran Stand: 1060x900x850 mm

SPESIFIKASI Chennai Metco Cold Cutting Baincut UM

Chennai Metco BAINCUT-UM Ordering Guide:

| Baincut UM Standard | Baincut UM Auto |

| Manual sturdy table model cutter for sectioning metals, ceramics and mineral samples | CNC Programmable table model cutter for sectioning metals, ceramics and mineral samples |

| Cutting capacity upto 80 mm | Cutting Capacity up to 80 mm dia |

| 5 HP, 3 Phase motor | 5 HP motor,3 Phase Motor |

| Spindle speed 2800 rpm | Spindle speed 2800 rpm |

| Cut-off wheel dia 12" | Cut-off wheel dia 12” |

| Splash proof, corrosion resistant with see through hood | Cutting action automatic (Longitudinal) |

| Cooling by two high flow water jets to provide optimum cooling | Cooling by two high flow water jets to provide optimum cooling |

| Y Movement (Longitudinal sectioning | Cutting Action Y Movement Automatic (Longitudinal sectioning) |

| One large 65mm coolant drain | Z Mvement by manual mode |

| Inbuilt movable recirculation coolant tank with 100 ltrs capacity. | Inbuilt movable recirculation coolant tank with 100 ltrs capacity. |

| Small opening in the side wall of the hood for sectioning extra long samples | Dimension: 1100 X 1250 X 840 mm. |

| T Slot Bed: 260mm X 260 mm with 8 mm T-slot | T slot bed: 260mm X 260mm X 260mm with 8mm T-slot |

| Machine Size : 850 X 1100 X 850 mm | Machine Size: 850 X 1400 X 810 mm. |

| Stand Size : 1060x900x850 mm | Stand Size: 1060 X 900 X 850 mm. |

Harga Chennai Metco Cold Cutting Baincut UM

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.