Untuk mendapatkan informasi lebih lengkap tentang:

Chennai Metco Petrography Cut Off Grinding Thin GEO

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

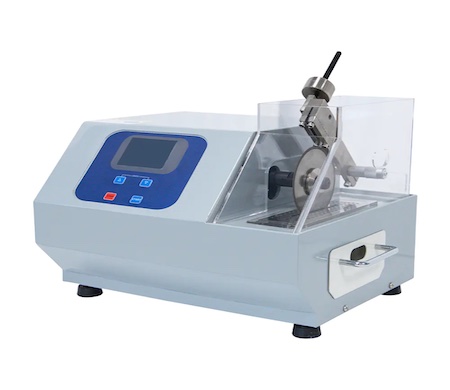

Chennai Metco Petrography Cut-Off Grinding Thin GEO adalah pemotong dan penggiling yang kokoh untuk pemotongan abrasif dari batuan, logam, bijih, fosil, keramik, dan sampel mineral untuk mengklasifikasikan informasi yang diperoleh selama analisis petrografi pada spesimen dengan ukuran hingga 30 mikron atau kurang. Ditenagai oleh motor servo 3 fase yang serbaguna 2 HP dan cakram abrasif halus, Chennai Metco Petrography Cut-Off Grinding Thin GEO cocok untuk pemotongan dan penggilingan spesimen berlapis dengan sifat berpasir dan nilai langka. Anda dapat mendapatkan hasil yang sangat prediktif dan kualitas permukaan makro yang dapat diulang dengan pengaturan kunci dan sekrup yang tepat. Anda dapat menggiling berbagai tingkat ketebalan berkat mikrometer internalnya. Pemotongan dan penggilingan dua fungsi dalam satu mesin memberikan keuntungan tersendiri dengan menggunakan sistem kompak untuk kedua proses dibandingkan menggunakan dua mesin terpisah. Spesimen dapat dipasang dengan vakum chuck dengan pompa vakum yang disediakan oleh mesin untuk menahan ukuran yang berbeda dari slide kaca. Slide kaca ini dipegang oleh chuck dan digerakkan melintasi pemotongan dan penggilingan. Setelah melalui pemotongan yang cermat, analisis yang mendetail terhadap mineral dapat lebih lanjut diperiksa dengan menggunakan optical mineralogy, sehingga tekstur mikro dan struktur dapat dihasilkan. Selain itu, cairan pendingin dapat didaur ulang melalui sistem penyaringan yang berguna untuk menghindari penyumbatan serbuk pada cairan pendingin. Hal ini meningkatkan masa pakai mesin, mengurangi aus dan robek, serta meningkatkan kualitas permukaan spesimen. Untuk persiapan permukaan yang lebih halus, langkah selanjutnya adalah menggiling dan memoles partikel abrasive dengan BAINPOL Auto PMV series hingga kualitas permukaan yang diinginkan siap dan struktur mikro spesimen dapat diamati dan diukur secara mendetail dengan Vision engineering TIM5 atau digital, optical, atau electron microscopy. Fitur-fitur Chennai Metco Petrography Cut-Off Grinding Thin GEO: Pemotongan dan penggilingan untuk ukuran spesimen hingga 30 mikron atau kurang Motor servo 3 fase 2 HP Mikrometer internal dengan sistem Pembacaan Digital untuk mudah mengukur ketebalan penggilingan spesimen Diameter Roda Pemotong Berlian menampung diameter dari 6 "hingga 10" Diameter Roda Penggiling Berlian dapat bervariasi dari 6 "hingga 8" Pemegang Spesimen dengan Vacuum Chuck untuk ukuran kaca slide yang berbeda Mikrometer internal dengan Pembacaan Digital Tangki pendingin sirkulasi dengan kapasitas 50 liter Pendingin didaur ulang melalui sistem penyaringan yang berguna untuk menghindari penyumbatan serbuk pada pendingin

Chennai Metco Petrography Cut-Off Grinding Thin GEO adalah pemotong dan penggiling yang kokoh untuk pemotongan abrasif dari batuan, logam, bijih, fosil, keramik, dan sampel mineral untuk mengklasifikasikan informasi yang diperoleh selama analisis petrografi pada spesimen dengan ukuran hingga 30 mikron atau kurang. Ditenagai oleh motor servo 3 fase yang serbaguna 2 HP dan cakram abrasif halus, Chennai Metco Petrography Cut-Off Grinding Thin GEO cocok untuk pemotongan dan penggilingan spesimen berlapis dengan sifat berpasir dan nilai langka. Anda dapat mendapatkan hasil yang sangat prediktif dan kualitas permukaan makro yang dapat diulang dengan pengaturan kunci dan sekrup yang tepat. Anda dapat menggiling berbagai tingkat ketebalan berkat mikrometer internalnya. Pemotongan dan penggilingan dua fungsi dalam satu mesin memberikan keuntungan tersendiri dengan menggunakan sistem kompak untuk kedua proses dibandingkan menggunakan dua mesin terpisah.

Spesimen dapat dipasang dengan vakum chuck dengan pompa vakum yang disediakan oleh mesin untuk menahan ukuran yang berbeda dari slide kaca. Slide kaca ini dipegang oleh chuck dan digerakkan melintasi pemotongan dan penggilingan. Setelah melalui pemotongan yang cermat, analisis yang mendetail terhadap mineral dapat lebih lanjut diperiksa dengan menggunakan optical mineralogy, sehingga tekstur mikro dan struktur dapat dihasilkan. Selain itu, cairan pendingin dapat didaur ulang melalui sistem penyaringan yang berguna untuk menghindari penyumbatan serbuk pada cairan pendingin. Hal ini meningkatkan masa pakai mesin, mengurangi aus dan robek, serta meningkatkan kualitas permukaan spesimen.

Untuk persiapan permukaan yang lebih halus, langkah selanjutnya adalah menggiling dan memoles partikel abrasive dengan BAINPOL Auto PMV series hingga kualitas permukaan yang diinginkan siap dan struktur mikro spesimen dapat diamati dan diukur secara mendetail dengan Vision engineering TIM5 atau digital, optical, atau electron microscopy.

Fitur-fitur Chennai Metco Petrography Cut-Off Grinding Thin GEO:

- Pemotongan dan penggilingan untuk ukuran spesimen hingga 30 mikron atau kurang

- Motor servo 3 fase 2 HP

- Mikrometer internal dengan sistem Pembacaan Digital untuk mudah mengukur ketebalan penggilingan spesimen

- Diameter Roda Pemotong Berlian menampung diameter dari 6 "hingga 10"

- Diameter Roda Penggiling Berlian dapat bervariasi dari 6 "hingga 8"

- Pemegang Spesimen dengan Vacuum Chuck untuk ukuran kaca slide yang berbeda

- Mikrometer internal dengan Pembacaan Digital

- Tangki pendingin sirkulasi dengan kapasitas 50 liter

- Pendingin didaur ulang melalui sistem penyaringan yang berguna untuk menghindari penyumbatan serbuk pada pendingin

SPESIFIKASI Chennai Metco Petrography Cut Off Grinding Thin GEO

Chennai Metco Petrography Cut Off Grinding Thin GEO Ordering Guide:

| Specification | Chennai Metco Petrography Cut Off Grinding Thin GEO |

| Working Area | Dry cutting with specimen diameter up to 30 micron |

| Power |

2 HP Motor, 3 Phase |

| Abrasive wheel |

Diamond cutting wheels of different diameter from 6” to 10”. Cup grinding wheel diameter can vary from 6” to 8” |

| Operation range | Specimen size up to 30 microns or less |

| Clamping vise | Stainless Steel Platform with vacuum pum and vacuum securing device |

Harga Chennai Metco Petrography Cut Off Grinding Thin GEO

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.