Untuk mendapatkan informasi lebih lengkap tentang:

Behringer High Performance Automatic Bandsaw Machine HBE663A Performance

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Temukan Potensi Pemotongan Terbaik dengan High-Performance Automatic Bandsaws HBE663A Performance Series: Ideal untuk Bahan Padat dan Bundel High-Performance Automatic Bandsaws HBE663A Performance Series, dengan desain yang kuat dan komponen dari bahan besi tuang abu-abu yang dapat meredam getaran, mesin ini dapat mengatasi pekerjaan yang paling berat sekalipun. Beberapa fiturnya yang canggih antara lain kontrol auto-feed dengan sistem servo-feed, pemantauan terus-menerus pada gaya pemotongan, pengangkatan serpihan yang efisien dan pembersihan gergaji pita, serta sistem pandu berjenis gantry yang presisi untuk makanan bahan yang akurat. Namun, yang membedakan HBE663A Performance adalah keahliannya dalam memotong bundel bahan. Dengan adanya dua klem dan rahang tetap yang dapat ditarik, bahkan bundel yang diikat dapat diposisikan dengan sangat akurat. Dan dengan bantuan perangkat pengunci vertikal yang kuat, bundel Anda akan tetap aman saat dipotong. Jika Anda memerlukan pemotongan dengan panjang yang lebih, tidak perlu khawatir. Penjepit pengumpan dapat dikonfigurasi dalam panjang 1.500 mm dan 3.000 mm sesuai kebutuhan Anda. Berikut beberapa fitur dari Behringer High Performance Automatic Bandsaw Machine HBE663A Performance, diantaranya: Sistem Umpan Turun Servo Umpan gergaji dilakukan dengan menggunakan sekrup bola dan motor servo. Hal ini menghasilkan waktu diam yang jauh lebih singkat dan umpan gergaji yang lebih presisi. Keuntungan Anda: kinerja pemotongan yang lebih tinggi dan masa pakai alat pisau bandsaw yang lebih lama. Panduan Cast Iron Bandsaw Diproduksi oleh Behringer, panduan pita menyediakan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat. Robust Feed Gripper Penanganan material yang tepat untuk benda kerja yang berat berkat gripper pengumpan yang kuat dengan rahang tetap yang dapat ditarik. Panjang pengumpanan dapat diperpanjang hingga 1.500 mm atau 3.000 mm secara opsional. Konveyor Serpih Yang Kuat (opsional) Pembuangan serpih yang optimal berkat dasar mesin berbentuk corong dan konveyor serpih berbentuk pengaduk dengan tangki pendingin terintegrasi. Ketinggian pelepasan sebesar 800 mm memungkinkan penggunaan ember serpih yang besar. Pembuangan serpih berada dalam arah aliran material. Penggunaan Karbida Blade Yang Ekonomis Capai kinerja potong yang tinggi saat memotong dengan pisau bimetal dan karbida. Hal ini dimungkinkan karena desain yang kokoh, penggunaan teknologi servo terbaru dan pembuangan serpih yang didimensikan dengan baik. Penggergajian Bundel yang Andal Pengunci ganda yang dapat diandalkan menawarkan keandalan proses - terutama saat memotong bundel atau membuat pemotongan tunggal. Rahang pengunci diatur pada sisi pemakanan dan sisi keluaran dan mengunci baik bahan awal maupun potongan yang sudah jadi. Pemotongan bundel yang andal dicapai berkat kombinasi pengunci ganda, rahang pengunci tetap yang dapat ditarik, dan perangkat pengunci vertikal yang kokoh. Kontrol Sentuh Intuitif BT65 Sikat Chip Berpenggerak Listrik Dengan perangkat cepat perubahan Behringer untuk perubahan sikat tanpa alat, gigi pisau gergaji pita dilindungi oleh sudut gesekan khusus. Fitur Lainnya: 3° Kemiringan Bandsaw Meningkatkan kinerja pemotongan saat mengerjakan profil dan balok berongga, dan mengurangi pembentukan gerinda. Kontrol Umpan Otomatis Pemilihan bahan dari basis data material yang luas. AFC secara otomatis menghitung nilai optimal untuk umpan gergaji dan kecepatan pemotongan. Sistem Panduan Desain Portal Presisi Kombinasi bingkai gergaji yang stabil dan minim getaran dengan sistem panduan linear dalam desain portal menjamin hasil pemotongan terbaik dan masa pakai maksimum. Mudah Digunakan Penggunaan semua fungsi dengan cepat dan mudah melalui kontrol sentuhan. Kontrol Tekanan Pemotongan Behringer yang Sensitif Sistem canggih ini secara otomatis menyesuaikan makan gergaji mesin dengan penampang material yang berubah, menghasilkan pemotongan yang lebih cepat dan akurat. Dengan penempatannya yang strategis langsung di belakang pisau, sistem ini dapat mengatur dengan cepat dan tepat, memastikan Anda mendapatkan hasil terbaik setiap kali. Lengan Panduan Otomatis Hasil pemotongan optimal tanpa penyesuaian apa pun - bahkan dengan ukuran material yang sering berubah. Klem Ganda Menawarkan kehandalan proses - terutama saat memotong tumpukan atau melakukan pemotongan tunggal. Rahang klem ditempatkan pada sisi masukan dan keluaran dan mengunci baik bahan awal maupun potongan yang sudah jadi. LFC adalah distributor eksklusif Behringer High Performance Automatic Bandsaw Machine HBE663A Performance di Singapura dan Malaysia. Dengan Behringer High Performance Automatic Bandsaw Machine HBE663A Performance, Anda dapat mengonfigurasi mesin Anda sesuai dengan persyaratan yang tepat dengan banyak pilihan, memastikan bahwa Anda mendapatkan hasil terbaik dari produksi Anda. Dan dengan tim ahli kami siap membantu Anda, Anda dapat yakin bahwa Anda membuat pilihan yang tepat. Jadi, mengapa menunggu? Hubungi kami hari ini untuk diskusi dan langkah pertama untuk memaksimalkan efisiensi produksi Anda!

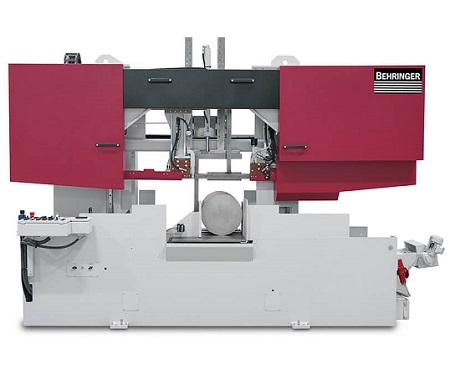

Temukan Potensi Pemotongan Terbaik dengan High-Performance Automatic Bandsaws HBE663A Performance Series: Ideal untuk Bahan Padat dan Bundel

High-Performance Automatic Bandsaws HBE663A Performance Series, dengan desain yang kuat dan komponen dari bahan besi tuang abu-abu yang dapat meredam getaran, mesin ini dapat mengatasi pekerjaan yang paling berat sekalipun. Beberapa fiturnya yang canggih antara lain kontrol auto-feed dengan sistem servo-feed, pemantauan terus-menerus pada gaya pemotongan, pengangkatan serpihan yang efisien dan pembersihan gergaji pita, serta sistem pandu berjenis gantry yang presisi untuk makanan bahan yang akurat.

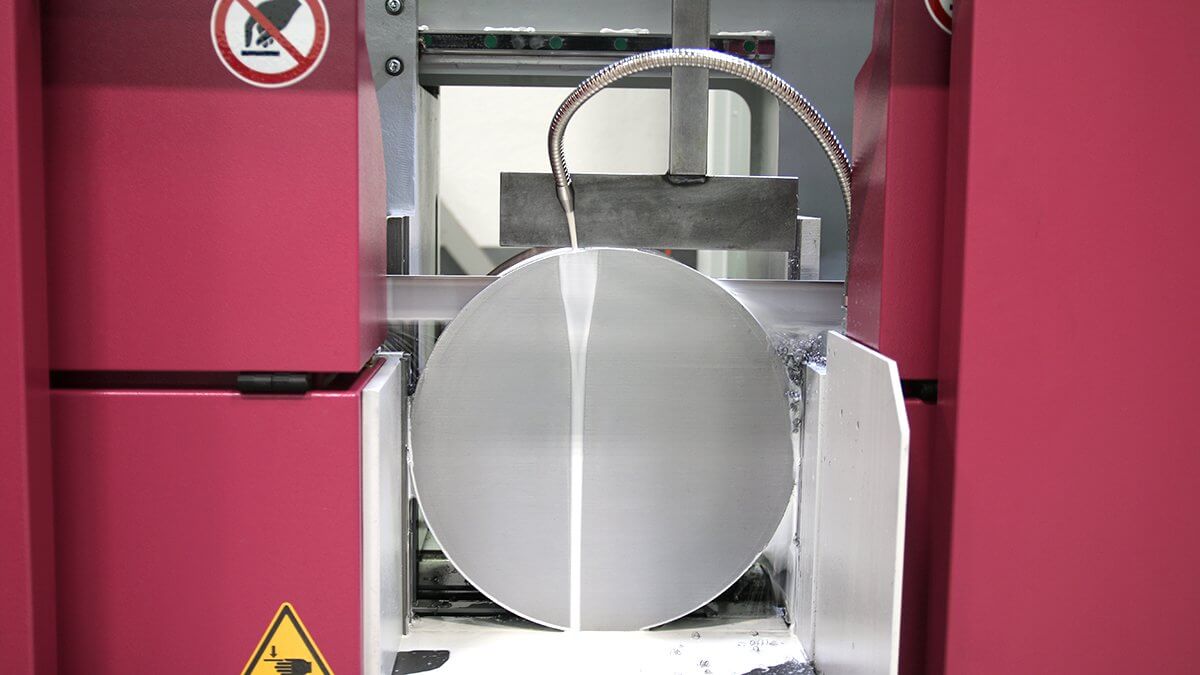

Namun, yang membedakan HBE663A Performance adalah keahliannya dalam memotong bundel bahan. Dengan adanya dua klem dan rahang tetap yang dapat ditarik, bahkan bundel yang diikat dapat diposisikan dengan sangat akurat. Dan dengan bantuan perangkat pengunci vertikal yang kuat, bundel Anda akan tetap aman saat dipotong.

Jika Anda memerlukan pemotongan dengan panjang yang lebih, tidak perlu khawatir. Penjepit pengumpan dapat dikonfigurasi dalam panjang 1.500 mm dan 3.000 mm sesuai kebutuhan Anda.

Berikut beberapa fitur dari Behringer High Performance Automatic Bandsaw Machine HBE663A Performance, diantaranya:

|

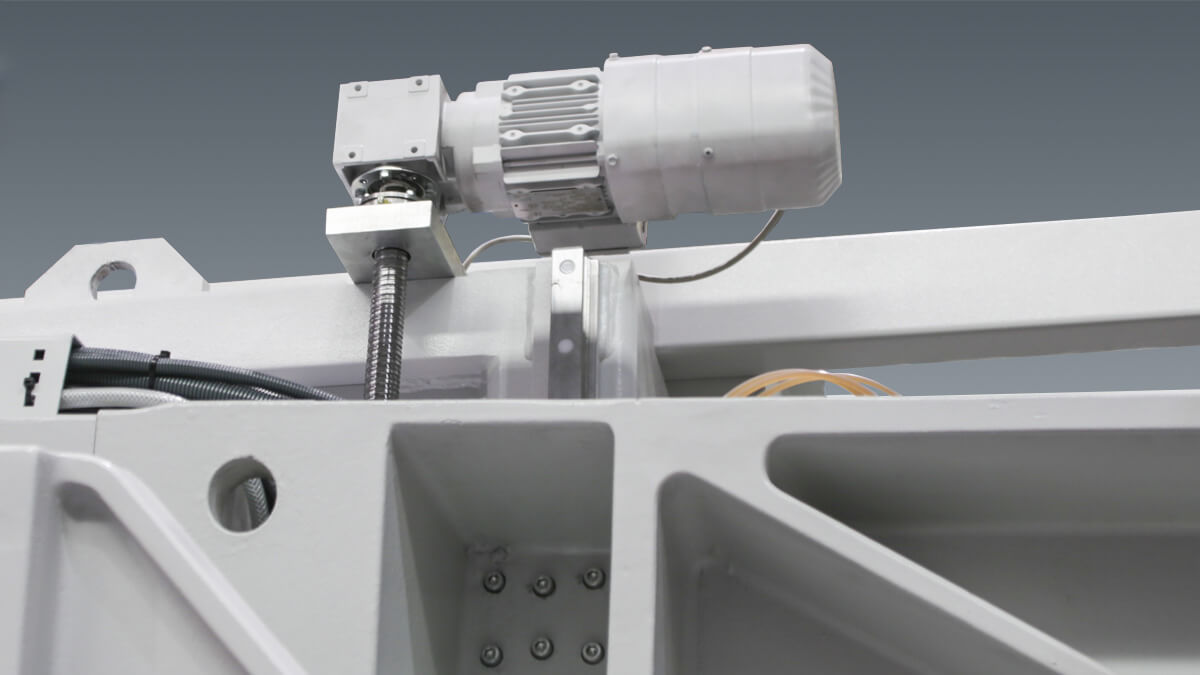

Sistem Umpan Turun Servo Umpan gergaji dilakukan dengan menggunakan sekrup bola dan motor servo. Hal ini menghasilkan waktu diam yang jauh lebih singkat dan umpan gergaji yang lebih presisi. Keuntungan Anda: kinerja pemotongan yang lebih tinggi dan masa pakai alat pisau bandsaw yang lebih lama. |

|

|

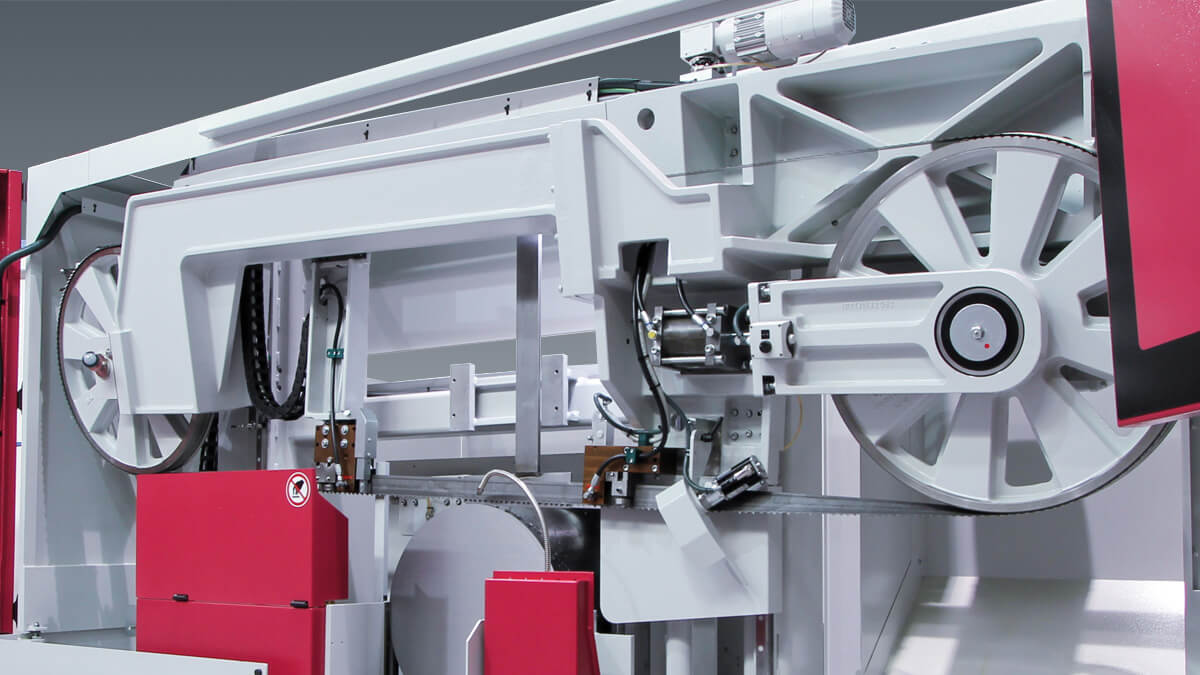

Panduan Cast Iron Bandsaw Diproduksi oleh Behringer, panduan pita menyediakan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat. |

|

Robust Feed Gripper Penanganan material yang tepat untuk benda kerja yang berat berkat gripper pengumpan yang kuat dengan rahang tetap yang dapat ditarik. Panjang pengumpanan dapat diperpanjang hingga 1.500 mm atau 3.000 mm secara opsional. |

|

|

Konveyor Serpih Yang Kuat (opsional) Pembuangan serpih yang optimal berkat dasar mesin berbentuk corong dan konveyor serpih berbentuk pengaduk dengan tangki pendingin terintegrasi. Ketinggian pelepasan sebesar 800 mm memungkinkan penggunaan ember serpih yang besar. Pembuangan serpih berada dalam arah aliran material. |

|

Penggunaan Karbida Blade Yang Ekonomis Capai kinerja potong yang tinggi saat memotong dengan pisau bimetal dan karbida. Hal ini dimungkinkan karena desain yang kokoh, penggunaan teknologi servo terbaru dan pembuangan serpih yang didimensikan dengan baik. |

|

|

Penggergajian Bundel yang Andal Pengunci ganda yang dapat diandalkan menawarkan keandalan proses - terutama saat memotong bundel atau membuat pemotongan tunggal. Rahang pengunci diatur pada sisi pemakanan dan sisi keluaran dan mengunci baik bahan awal maupun potongan yang sudah jadi. Pemotongan bundel yang andal dicapai berkat kombinasi pengunci ganda, rahang pengunci tetap yang dapat ditarik, dan perangkat pengunci vertikal yang kokoh. |

| Kontrol Sentuh Intuitif BT65 |

|

|

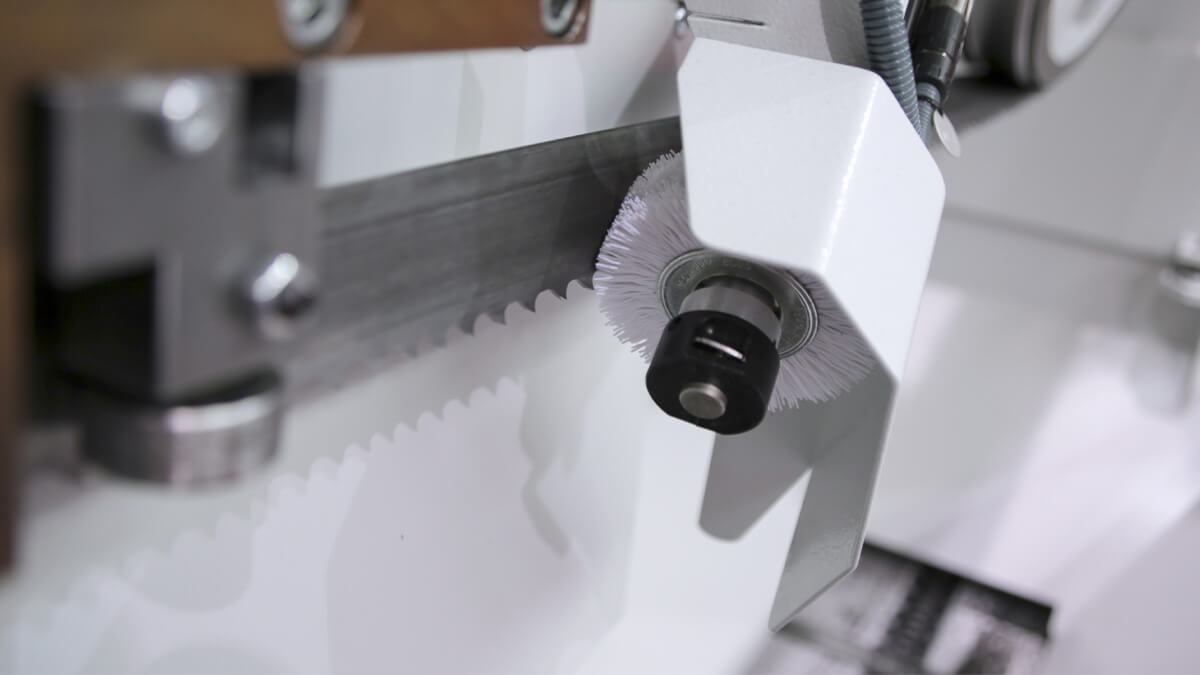

Sikat Chip Berpenggerak Listrik Dengan perangkat cepat perubahan Behringer untuk perubahan sikat tanpa alat, gigi pisau gergaji pita dilindungi oleh sudut gesekan khusus. |

Fitur Lainnya:

3° Kemiringan Bandsaw

Meningkatkan kinerja pemotongan saat mengerjakan profil dan balok berongga, dan mengurangi pembentukan gerinda.

Kontrol Umpan Otomatis

Pemilihan bahan dari basis data material yang luas. AFC secara otomatis menghitung nilai optimal untuk umpan gergaji dan kecepatan pemotongan.

Sistem Panduan Desain Portal Presisi

Kombinasi bingkai gergaji yang stabil dan minim getaran dengan sistem panduan linear dalam desain portal menjamin hasil pemotongan terbaik dan masa pakai maksimum.

Mudah Digunakan

Penggunaan semua fungsi dengan cepat dan mudah melalui kontrol sentuhan.

Kontrol Tekanan Pemotongan Behringer yang Sensitif

Sistem canggih ini secara otomatis menyesuaikan makan gergaji mesin dengan penampang material yang berubah, menghasilkan pemotongan yang lebih cepat dan akurat. Dengan penempatannya yang strategis langsung di belakang pisau, sistem ini dapat mengatur dengan cepat dan tepat, memastikan Anda mendapatkan hasil terbaik setiap kali.

Lengan Panduan Otomatis

Hasil pemotongan optimal tanpa penyesuaian apa pun - bahkan dengan ukuran material yang sering berubah.

Klem Ganda

Menawarkan kehandalan proses - terutama saat memotong tumpukan atau melakukan pemotongan tunggal. Rahang klem ditempatkan pada sisi masukan dan keluaran dan mengunci baik bahan awal maupun potongan yang sudah jadi.

LFC adalah distributor eksklusif Behringer High Performance Automatic Bandsaw Machine HBE663A Performance di Singapura dan Malaysia. Dengan Behringer High Performance Automatic Bandsaw Machine HBE663A Performance, Anda dapat mengonfigurasi mesin Anda sesuai dengan persyaratan yang tepat dengan banyak pilihan, memastikan bahwa Anda mendapatkan hasil terbaik dari produksi Anda. Dan dengan tim ahli kami siap membantu Anda, Anda dapat yakin bahwa Anda membuat pilihan yang tepat. Jadi, mengapa menunggu? Hubungi kami hari ini untuk diskusi dan langkah pertama untuk memaksimalkan efisiensi produksi Anda!

SPESIFIKASI Behringer High Performance Automatic Bandsaw Machine HBE663A Performance

| Cutting Range | |

| Cutting range 90° round | 660 mm |

| Cutting range 90° flat | 710 x 660 mm |

| Smallest dimension to be sawn round | 20 mm |

| Smallest dimension to be sawn flat | 20 x 20 mm |

| Performance Characteristics | |

| Feeding length single stroke | 540 mm (option 1,500/3,000 mm) |

| Drive Power | 5.5 kW |

| Blade Speed | 10 - 110 m/min |

| Saw Blade Dimension | 8,750 x 54 x 1.6 mm |

| Rest piece length in automatic operation | 50 mm |

| Total power |

12 kW |

| Saw feed | servo-feed via ball screw |

| Material feed |

ball screw |

| Material clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimension & Weight | |

| Length | 2,250 mm |

| Width | 4,400 mm |

| Height | 2,760 mm |

| Weight | 6,500 kg |

| Material support height | 800 mm |

Harga Behringer High Performance Automatic Bandsaw Machine HBE663A Performance

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.