Untuk mendapatkan informasi lebih lengkap tentang:

Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Horizontal Automatic Miter Bandsaws HBE Series Potongan sudut miter otomatis dalam konstruksi baja dan perdagangan baja profil Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dalam konstruksi baja dan perdagangan baja menjamin pengoperasian sistem yang tinggi dan pemotongan sudut yang tepat dalam operasi sepenuhnya otomatis. Untuk tujuan ini, Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dikombinasikan dengan gripper pengumpan yang dikendalikan oleh NC dan kontrol PC yang kuat. Seri HBE-GA mencakup berbagai aplikasi, mulai dari sistem untuk memproses profil kecil dan menengah dalam konstruksi logam hingga baja struktural dalam konstruksi gedung dan jembatan. Terutama saat memotong tabung bulat atau paket material, penempatan material dengan menggunakan gripper pengumpan adalah solusi teknis terbaik. Untuk pemotongan miter otomatis dalam konstruksi logam, perdagangan baja penampang dan teknik mesin Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA memiliki performa pemotongan yang tinggi, mudah digunakan dan presisi yang tinggi. Mesin ini dapat memotong baja profil, pipa dan bahan padat yang terbuat dari baja atau baja tahan karat hampir di semua sudut. Berkat gripper feed yang presisi dan penyesuaian sudut potong yang cepat yang dikontrol NC, mesin ini sepenuhnya otomatis. Dengan sistem pengumpan gergaji standar yang dilengkapi penggerak servo dan kontrol tekanan pemotongan Behringer yang unik, mesin ini dapat memotong baja berbentuk hingga dua kali lebih cepat dibandingkan mesin gergaji konvensional dengan harga yang sama. Dengan kontrol PC yang kuat, HBE320-523GA sudah siap untuk dilengkapi dengan peralatan penanganan material. Berikut adalah beberapa fitur Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA, antara lain: Sistem Servo Feed Gergaji diumpankan oleh penggerak servo dengan sekrup bola. Hal ini menghasilkan waktu henti yang jauh lebih singkat dan umpan gergaji yang lebih akurat. Sistem servo feed Behringer juga dilengkapi dengan kontrol tekanan pemotongan. Hal ini meningkatkan kinerja pemotongan saat memotong pipa dan profil, karena secara otomatis menyesuaikan pemotongan mesin dengan penampang material yang berubah-ubah. Karena sistem ini ditempatkan langsung di belakang pisau, sistem ini dapat mengatur dengan cepat dan presisi. Kontrol PC yang Kuat Penyesuaian Sudut Miter Otomatis Sistem Semprotan Mikro Saat memotong profil, pipa dan bahan padat, sistem pelumasan kuantitas minimum standar memberikan hasil terbaik. Mata pisau gergaji secara terus-menerus dibasahi dengan minyak pemotong melalui dua nozzle. Ini menjamin masa pakai yang lama untuk mata pisau gergaji dan lingkungan kerja yang bersih. Meja Material Penyangga meja tertutup membuat penggunaan gergaji band miter menjadi lebih mudah. Bahkan bagian-bagian pendek dapat diangkut masuk dan keluar dari mesin tanpa masalah. Sikat Serpihan yang Digerakkan dengan Listrik Dengan perangkat pengganti sikat tanpa alat Behringer yang cepat, gigi pisau bandsaw dilindungi oleh sudut pengaitan khusus. Roller Angkat pada Sisi Masukan Garis Laser (Opsi) Cast Iron Bandsaw Guide Diproduksi oleh Behringer yang memberikan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat. Fitur Lainnya: Sistem Panduan Portal-Presisi Kombinasi antara rangka gergaji yang stabil dan rendah getaran serta sistem panduan linier dalam desain portal, memastikan hasil pemotongan terbaik dan masa pakai maksimal. Kemiringan Mata Gergaji 3° Memberikan kinerja pemotongan yang lebih tinggi saat menggergaji profil dan balok berongga serta mengurangi pembentukan gerinda. Memberikan cengkeram dengan rahang tetap yang dapat ditarik mundur Untuk penempatan otomatis bahan awal, Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA memiliki cengkeram pakan sepanjang 3.000 mm. Karena adanya rahang tetap yang dapat ditarik mundur, bahkan profil yang sedikit bengkok dapat diumpankan dengan andal ke dalam mesin. Konsep Pemotongan yang Berorientasi pada Pelanggan Behringer menawarkan solusi sistem lengkap dengan penanganan material individu di mana semua bahan cocok dengan sempurna. Kami adalah mitra yang kompeten dan memberikan masukan yang komprehensif. Lengan Pemandu Otomatis Menghasilkan pemotongan terbaik tanpa penyesuaian - bahkan dengan ukuran material yang sering berubah. Pengencangan Pisau Hidrolik Bandsaw selalu dikencangkan secara optimal oleh sistem hidrolik. Saat mesin berhenti, bandsaw dilepaskan tegangannya, sehingga masa pakainya menjadi lebih panjang. Jika terjadi putusnya bandsaw, mesin akan berhenti secara otomatis. Penggerak yang Hemat Energi Hasil lebih banyak dengan konsumsi energi yang lebih sedikit. Melindungi lingkungan dan dompet Anda. LFC adalah distributor eksklusif untuk Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA di Singapura dan Malaysia. Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dapat dikonfigurasi dengan sempurna sesuai dengan kebutuhan Anda dengan berbagai opsi. Inilah cara untuk mendapatkan hasil terbaik dari produksi Anda. Tim kami akan senang untuk memberi saran kepada Anda. Hubungi kami untuk diskusi!

Horizontal Automatic Miter Bandsaws HBE Series

Potongan sudut miter otomatis dalam konstruksi baja dan perdagangan baja profil

Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dalam konstruksi baja dan perdagangan baja menjamin pengoperasian sistem yang tinggi dan pemotongan sudut yang tepat dalam operasi sepenuhnya otomatis. Untuk tujuan ini, Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dikombinasikan dengan gripper pengumpan yang dikendalikan oleh NC dan kontrol PC yang kuat. Seri HBE-GA mencakup berbagai aplikasi, mulai dari sistem untuk memproses profil kecil dan menengah dalam konstruksi logam hingga baja struktural dalam konstruksi gedung dan jembatan. Terutama saat memotong tabung bulat atau paket material, penempatan material dengan menggunakan gripper pengumpan adalah solusi teknis terbaik.

Untuk pemotongan miter otomatis dalam konstruksi logam, perdagangan baja penampang dan teknik mesin

Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA memiliki performa pemotongan yang tinggi, mudah digunakan dan presisi yang tinggi. Mesin ini dapat memotong baja profil, pipa dan bahan padat yang terbuat dari baja atau baja tahan karat hampir di semua sudut. Berkat gripper feed yang presisi dan penyesuaian sudut potong yang cepat yang dikontrol NC, mesin ini sepenuhnya otomatis. Dengan sistem pengumpan gergaji standar yang dilengkapi penggerak servo dan kontrol tekanan pemotongan Behringer yang unik, mesin ini dapat memotong baja berbentuk hingga dua kali lebih cepat dibandingkan mesin gergaji konvensional dengan harga yang sama. Dengan kontrol PC yang kuat, HBE320-523GA sudah siap untuk dilengkapi dengan peralatan penanganan material.

Berikut adalah beberapa fitur Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA, antara lain:

|

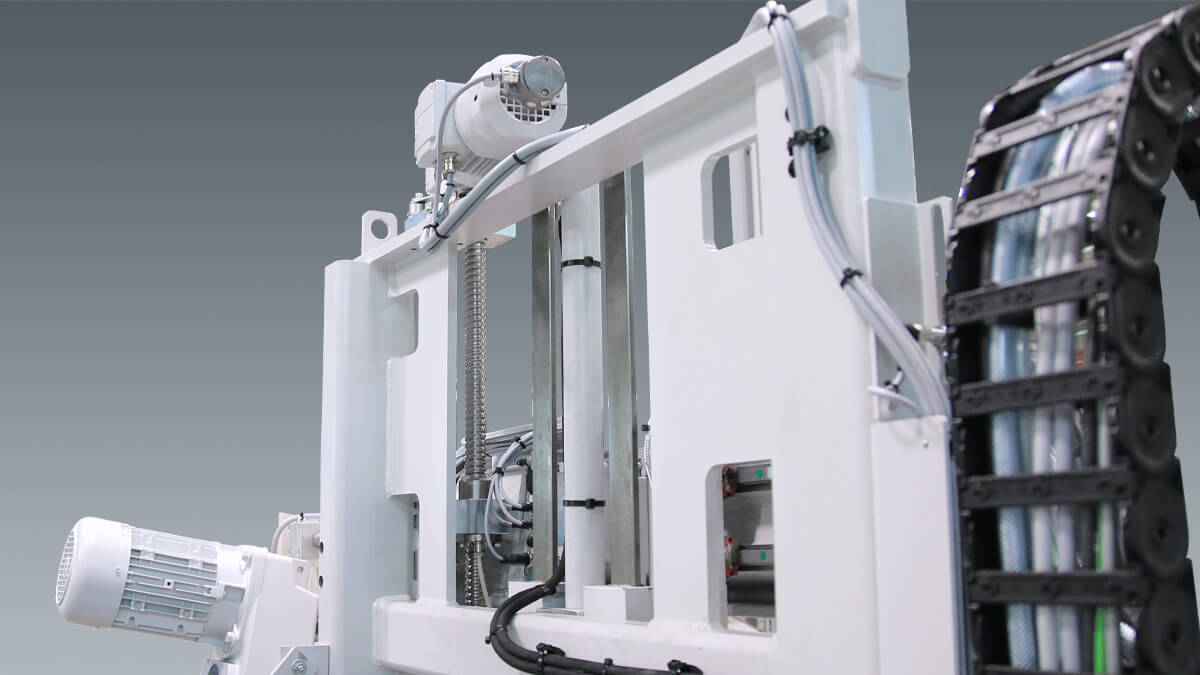

Sistem Servo Feed Gergaji diumpankan oleh penggerak servo dengan sekrup bola. Hal ini menghasilkan waktu henti yang jauh lebih singkat dan umpan gergaji yang lebih akurat. Sistem servo feed Behringer juga dilengkapi dengan kontrol tekanan pemotongan. Hal ini meningkatkan kinerja pemotongan saat memotong pipa dan profil, karena secara otomatis menyesuaikan pemotongan mesin dengan penampang material yang berubah-ubah. Karena sistem ini ditempatkan langsung di belakang pisau, sistem ini dapat mengatur dengan cepat dan presisi. |

|

|

|

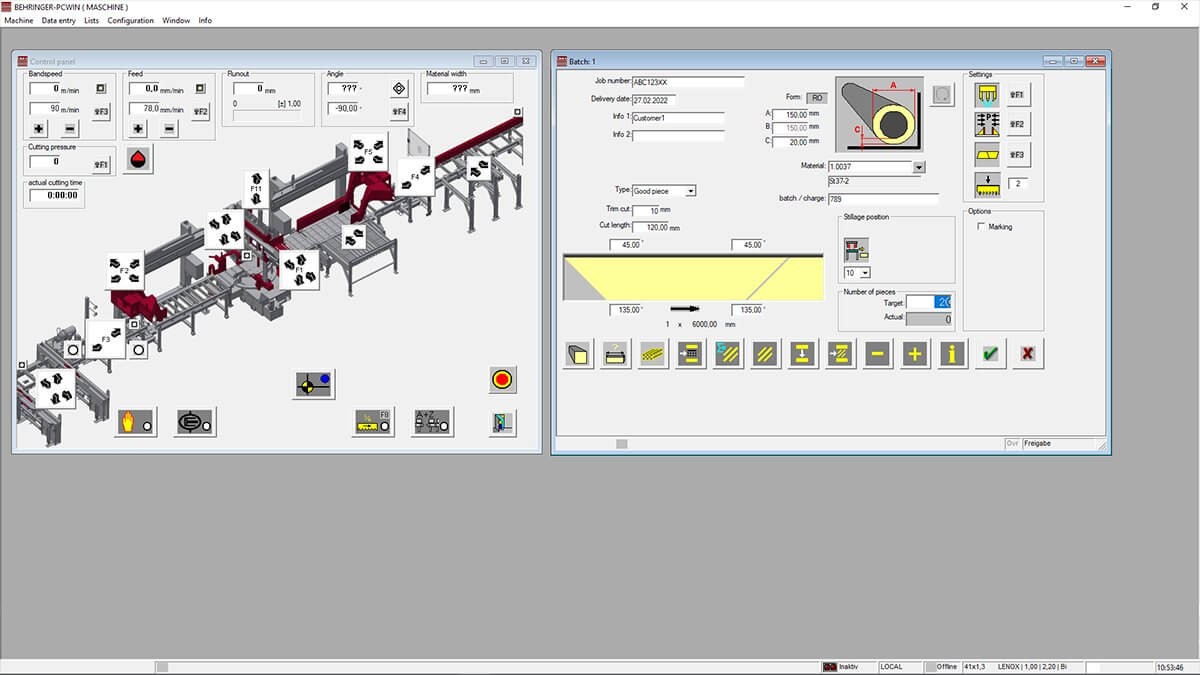

Kontrol PC yang Kuat |

|

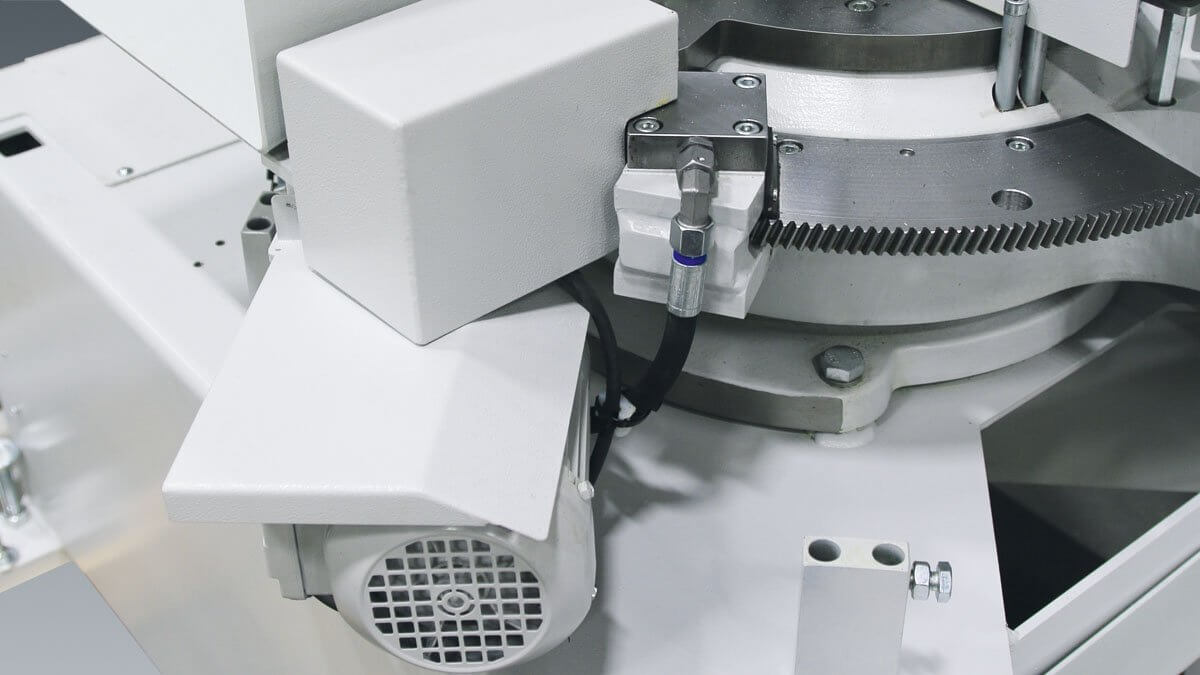

Penyesuaian Sudut Miter Otomatis |

|

|

Sistem Semprotan Mikro Saat memotong profil, pipa dan bahan padat, sistem pelumasan kuantitas minimum standar memberikan hasil terbaik. Mata pisau gergaji secara terus-menerus dibasahi dengan minyak pemotong melalui dua nozzle. Ini menjamin masa pakai yang lama untuk mata pisau gergaji dan lingkungan kerja yang bersih. |

|

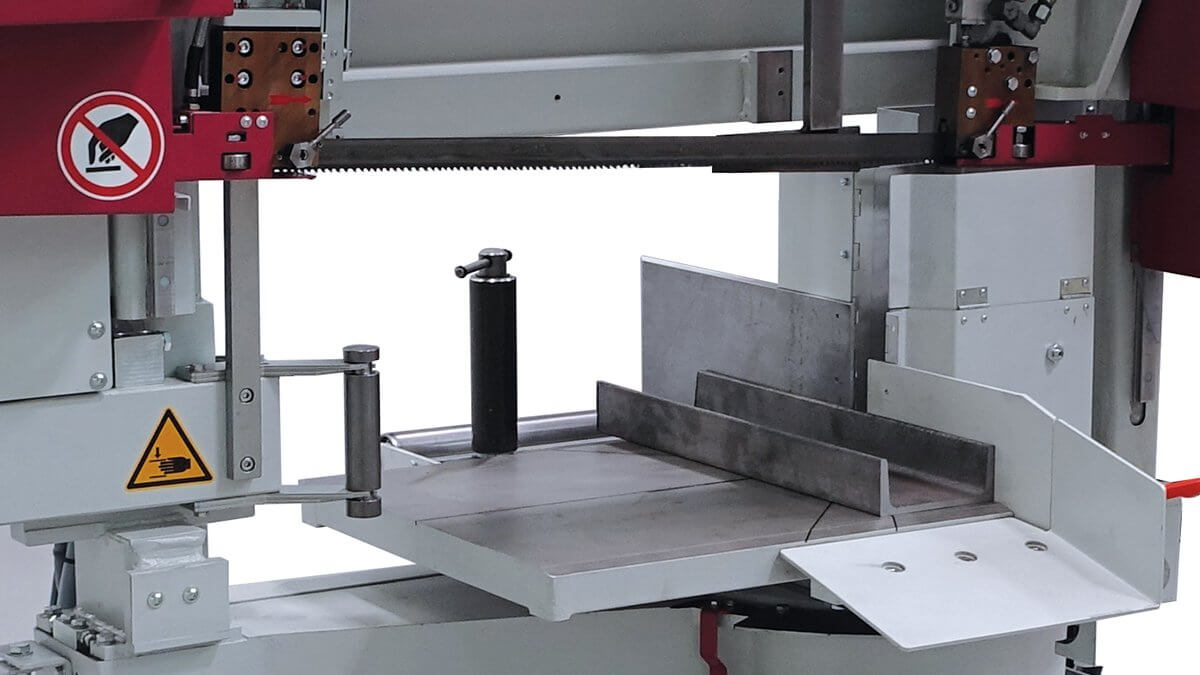

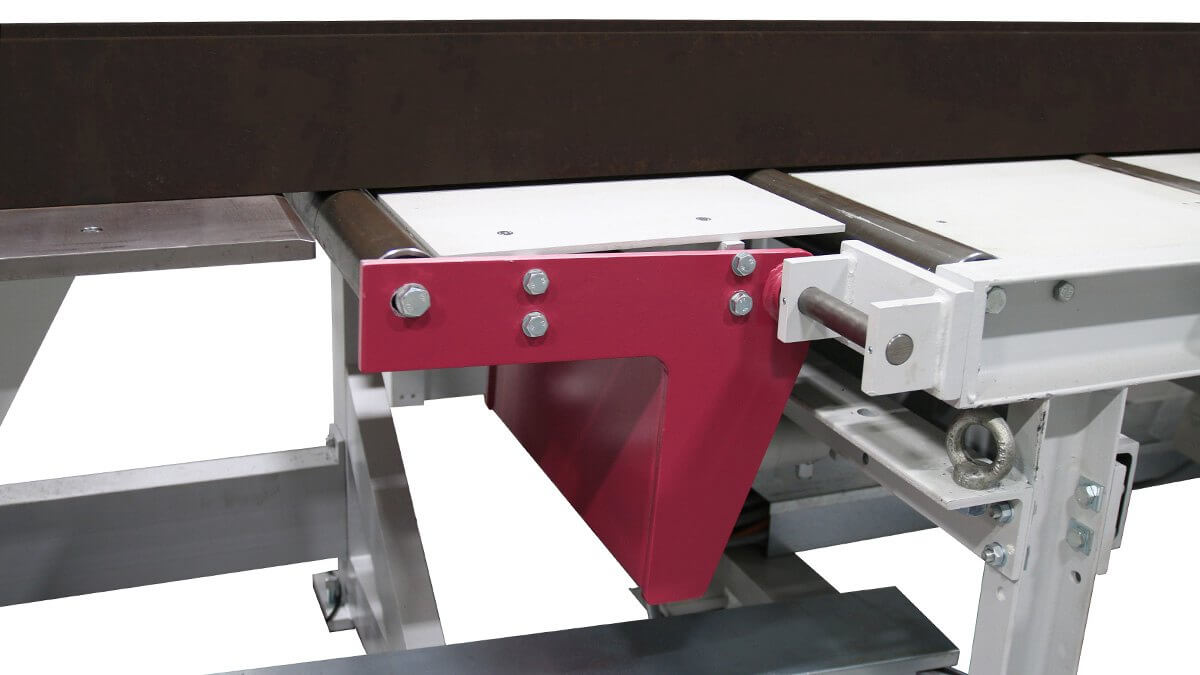

Meja Material Penyangga meja tertutup membuat penggunaan gergaji band miter menjadi lebih mudah. Bahkan bagian-bagian pendek dapat diangkut masuk dan keluar dari mesin tanpa masalah. |

|

|

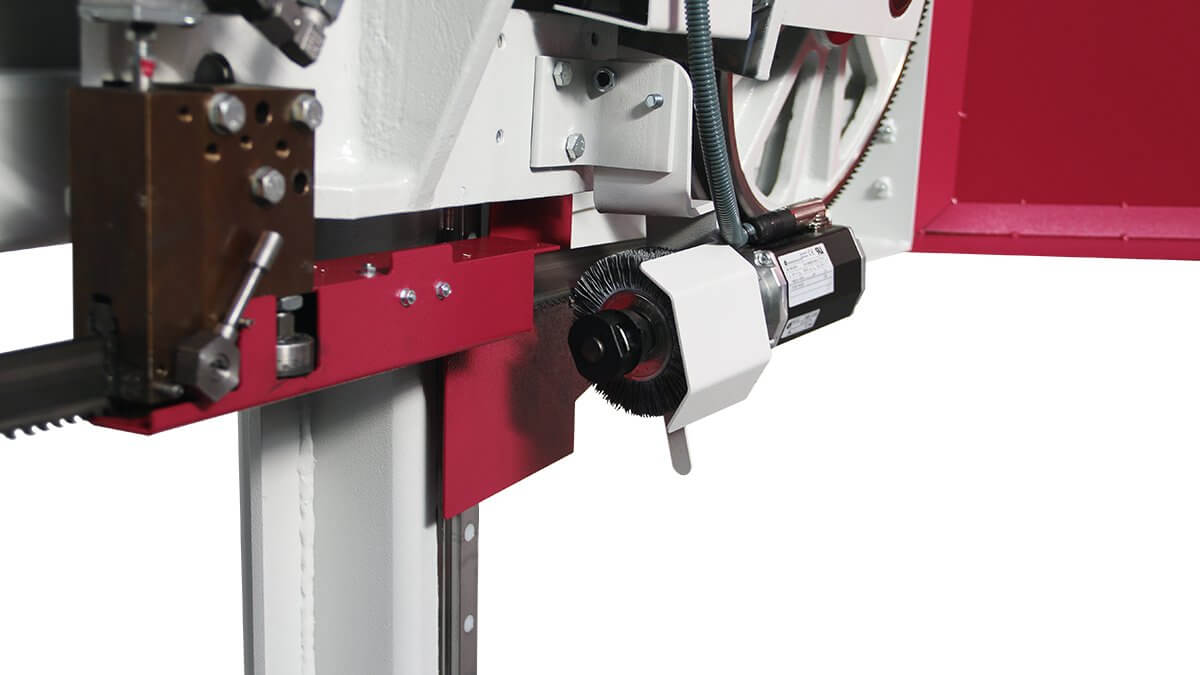

Sikat Serpihan yang Digerakkan dengan Listrik Dengan perangkat pengganti sikat tanpa alat Behringer yang cepat, gigi pisau bandsaw dilindungi oleh sudut pengaitan khusus. |

|

Roller Angkat pada Sisi Masukan |

|

|

Garis Laser (Opsi) |

|

|

Cast Iron Bandsaw Guide Diproduksi oleh Behringer yang memberikan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat. |

Fitur Lainnya:

Sistem Panduan Portal-Presisi

Kombinasi antara rangka gergaji yang stabil dan rendah getaran serta sistem panduan linier dalam desain portal, memastikan hasil pemotongan terbaik dan masa pakai maksimal.

Kemiringan Mata Gergaji 3°

Memberikan kinerja pemotongan yang lebih tinggi saat menggergaji profil dan balok berongga serta mengurangi pembentukan gerinda.

Memberikan cengkeram dengan rahang tetap yang dapat ditarik mundur

Untuk penempatan otomatis bahan awal, Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA memiliki cengkeram pakan sepanjang 3.000 mm. Karena adanya rahang tetap yang dapat ditarik mundur, bahkan profil yang sedikit bengkok dapat diumpankan dengan andal ke dalam mesin.

Konsep Pemotongan yang Berorientasi pada Pelanggan

Behringer menawarkan solusi sistem lengkap dengan penanganan material individu di mana semua bahan cocok dengan sempurna. Kami adalah mitra yang kompeten dan memberikan masukan yang komprehensif.

Lengan Pemandu Otomatis

Menghasilkan pemotongan terbaik tanpa penyesuaian - bahkan dengan ukuran material yang sering berubah.

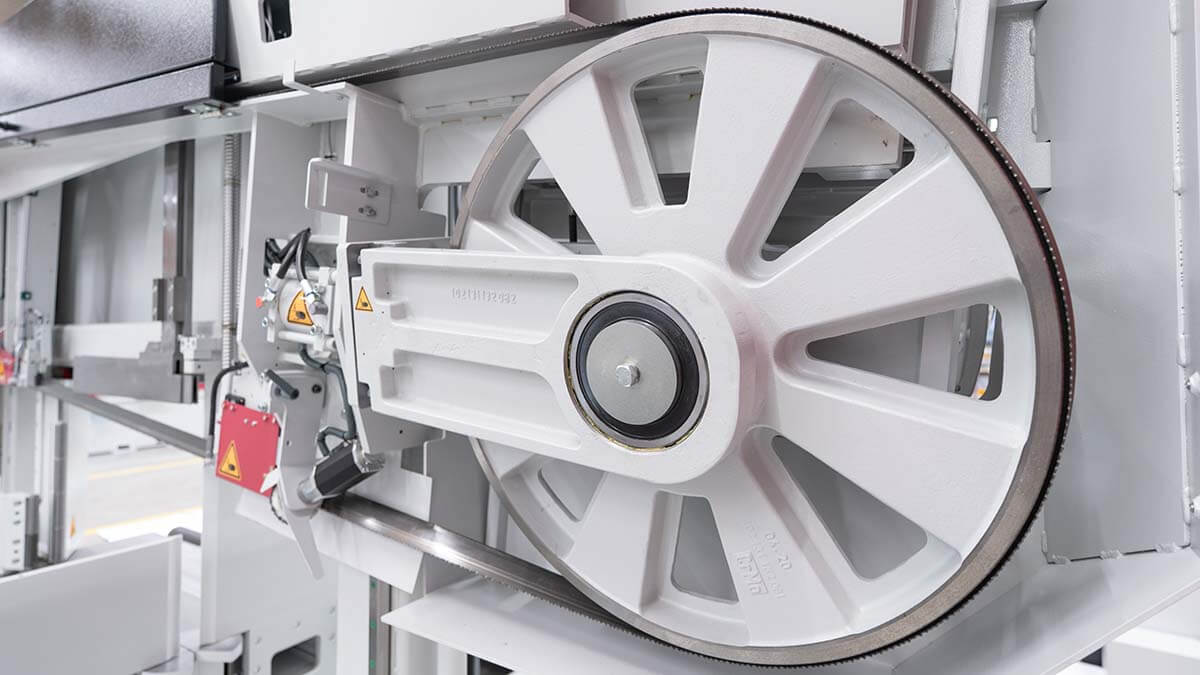

Pengencangan Pisau Hidrolik

Bandsaw selalu dikencangkan secara optimal oleh sistem hidrolik. Saat mesin berhenti, bandsaw dilepaskan tegangannya, sehingga masa pakainya menjadi lebih panjang. Jika terjadi putusnya bandsaw, mesin akan berhenti secara otomatis.

Penggerak yang Hemat Energi

Hasil lebih banyak dengan konsumsi energi yang lebih sedikit. Melindungi lingkungan dan dompet Anda.

LFC adalah distributor eksklusif untuk Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA di Singapura dan Malaysia. Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA dapat dikonfigurasi dengan sempurna sesuai dengan kebutuhan Anda dengan berbagai opsi. Inilah cara untuk mendapatkan hasil terbaik dari produksi Anda. Tim kami akan senang untuk memberi saran kepada Anda. Hubungi kami untuk diskusi!

SPESIFIKASI Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA

| Cutting Range | |

| Cutting range 90° round | 320 mm |

| Cutting range 90° flat | 520 x 320 mm |

| 75° Mitre left round / flat | 320 mm / 520 x 320 mm |

| 60° Mitre left round / flat | 320 mm / 470 x 320 mm |

| 45° Mitre left round / flat | 320 mm / 390 x 320 mm |

| 30° Mitre left round / flat | 200 mm / 200 x 320 mm |

| 75° Mitre right round / flat | 320 mm / 490 x 320 mm |

| 75° Mitre right round / flat | 320 mm / 420 x 320 mm |

| 75° Mitre right round / flat | 320 mm / 330 x 320 mm |

| Smallest Dimension to be sawn round | 20 mm |

| Smallest Dimension to be sawn flat | 20 x 20 mm |

| Performance Characteristics | |

| Feeding length single stroke | 3,000 mm |

| Drive Power | 2.6 kW |

| Blade Speed | 15 - 110 m/min |

| Saw Blade Dimension | 5,300 x 34 x 1.1 mm |

| Rest piece length | 150 mm |

| Total power |

8 kW |

| Saw Feed | servo-feed via ball screw |

| Material Feed | servo motor via gear rack |

| Material Clamping | hydraulic |

| Saw blade cleaning | electrically driven chip brush |

| Dimension & Weight | |

| Length | 5,500 mm (incl. swivel range: 6,000 mm) |

| Width | 2,900 mm |

| Height | 2,150 mm |

| Weight | 2,560 kg |

| Material support height | 800 mm |

Harga Behringer Horizontal Automatic Mitre Bandsaws HBE320-523GA

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.