Untuk mendapatkan informasi lebih lengkap tentang:

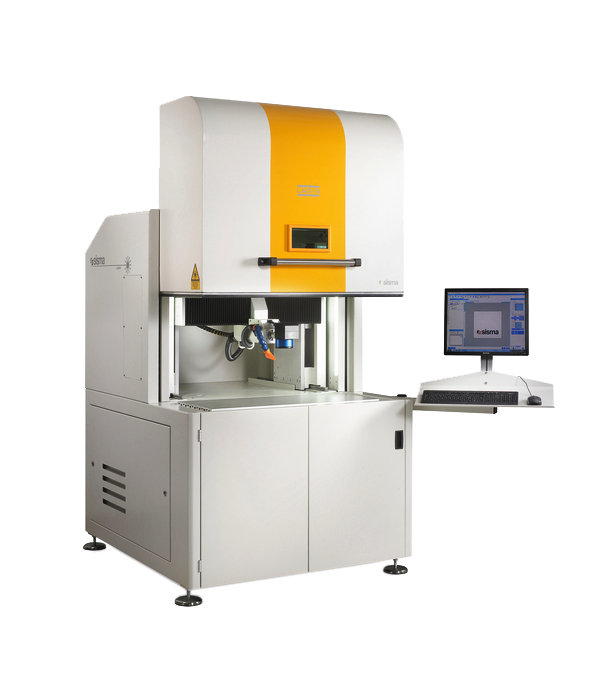

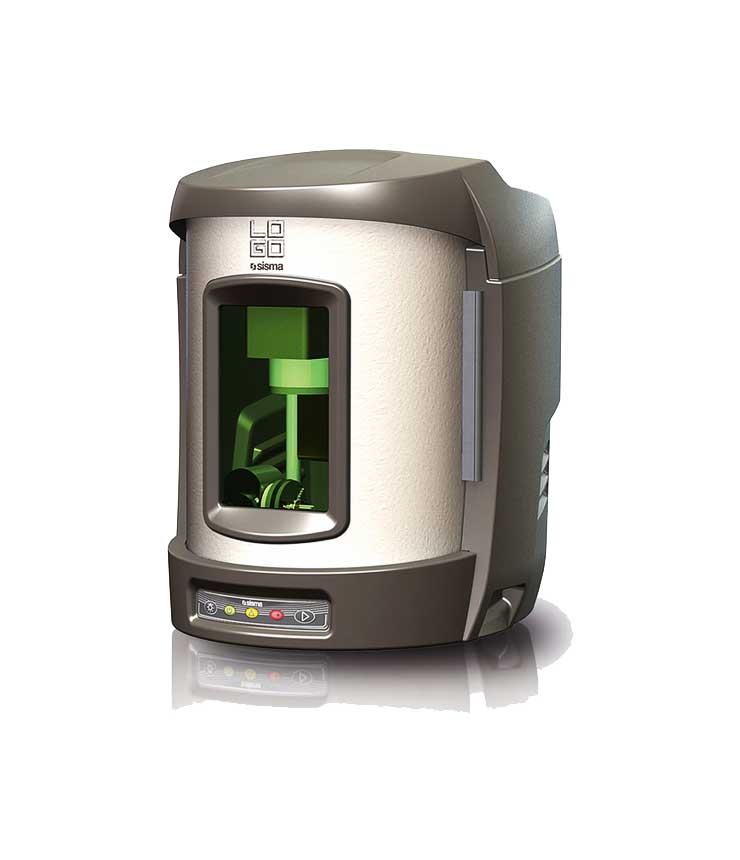

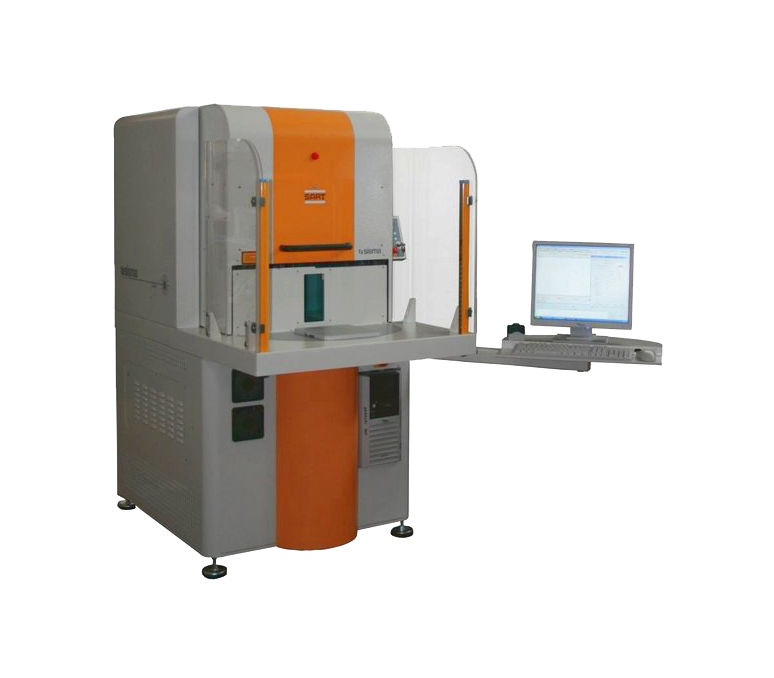

Sisma Laser Engraving Working Station LWS

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

SPESIFIKASI Sisma Laser Engraving Working Station LWS

Harga Sisma Laser Engraving Working Station LWS

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.