Untuk mendapatkan informasi lebih lengkap tentang:

DoALL Diamond Saw Blade Series

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

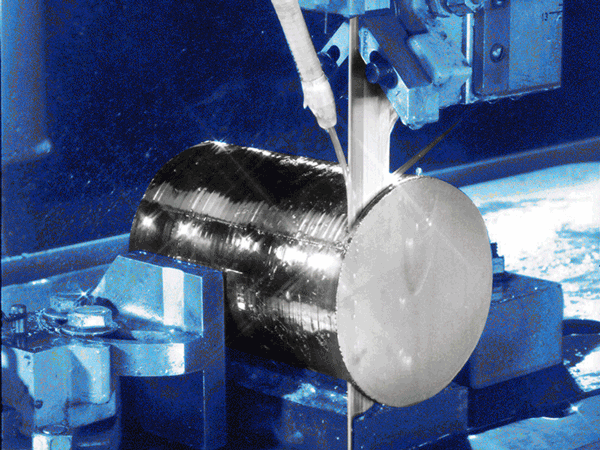

DoALL Diamond Saw Blade is compatible for various bandsaws and reciprocating saws. Depends on your machinery set up, DoALL diamonds Saw Blade performs consistently balanced between power to cut ratio for a cost effective job on cutting solid. The DoALL Diamond Saw Blade is manufactured from a high speed steel material coated with diamonds. DoALL diamonds Saw use nickel electroplated technology to transfer the diamond shards onto its steel blade base. This method produce a very thin and consistently sharp surface which actually consists of zillion cutting edges with tens of micrometres thick. By this innovative approach, DoALL Diamond Saw Blade enable you to work on highly abrasive material which on comparable saw needs longer hour with higher cost.

DoALL Diamond Saw Blade is suitable for cutting silicum, glass, fiberglass, quartz, abrasive composites, graphite, carbide, marble, carbon-granite, concrete, asphalt, masonry, and gem-cutting and ceramic. With free-flow water coolant, DoALL Diamond Saw Blade will give you the reliability and versatility in working on granite slab, carbon composites sheet, asbestos automotive brakes, electrical ceramic bobbins, marine fiberglass industry, aerospace equipment, resin tubes and many other application which may varies.

Features

- Diamond grit edge

- Continuous for materials up to 25 mm, segmenteed for large materials

Benefits

- Grinds hardest, most brittle, abrasive materials known

Applications

- Silicon, glass, quartz, abrasive composites, hard graphites, carbide, marble, limestone, brake linings etc

- Not for steel!

SPESIFIKASI DoALL Diamond Saw Blade Series

DoALL Penetrator Saw Blade Ordering Guide:

| Metric | Type | Selectable Diamond Grit size | |||||

| Width | Gauge | 25/30 | 40/50 | 60/80 | 100/120 | 200 | |

| 13 | 0,5 | Continuous | 406-942 | 406-918 | OR | OR | |

| 19 | 0,5 | Continuous | 406-959 | 406-926 | 406-750 | 406-769 | |

| Segmented | 406-741 | OR | OR | OR | |||

| 1,0 | Continuous | 406-422 | OR | OR | OR | OR | |

| 25 | 0,5 | Continuous | 406-967 | 406-934 | 406-971 | OR | |

| Segmented | 406-827 | 406-843 | 406-846 | OR | |||

| 1,0 | Continuous | 406-421 | 406-552 | 406-462 | OR | OR | |

| Segmented | 406-422 | OR | 406-433 | OR | OR | ||

| 32 | 0,5 | Continuous | 406-807 | 406-804 | 406-802 | OR | |

| Segmented | 406-813 | ||||||

| 1,0 | Continuous | 406-428 | OR | 406-476 | OR | OR | |

| Segmented | 406-447 | OR | 406-483 | OR | OR | ||

| 38 | 0,5 | Continuous | 406-817 | OR | OR | OR | |

| 1,0 | Segmented | 406-480 | OR | OR | OR | OR | |

| Continuous | 406-456 | OR | OR | OR | OR | ||

| 50 | 1,0 | Continuous | 406-496 | OR | 406-830 | OR | OR |

| Segmented | 406-837 | OR | 406-833 | OR | OR | ||

| Kerf | Factor | Milimeters | 1,6 | 0,9 | 0,6 | 0,4 | 0,2 |

| OR | Colored areas available on request (minimum order required) | ||||||

| Note | To determine approximate kerf: add kerf factor to gauge of the band | ||||||

|

NOTES: Be advised that freeflow of water as a coolant will prevent the DoALL diamond blade from overheating, greatly reduce the amount of harmful dust created by cutting, remove the slurry from the cut, and extend the life of the blade at the same time. |

You can also download DoALL Saw Blade catalogs here

Harga DoALL Diamond Saw Blade Series

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.