What is hardness and hardness testing?

Hardness refers to the stiffness and strength of materials. It is a sensory expression that can be felt visually in extreme cases. People sense objects as being harder when the hand touches it and the finger deforms more than the object. As hardness is judged from the relative statues of deformation between the probe and the object, the hardness of an object changes based on the hardness of the probe. In other words, hardness is relative, and not absolute. In order to make hardness absolute, we need to measure it using a hard probe, something that does not deform against any object. The hardness will then be judged quantitatively from the deformation of the object. This sets the stage for fundamental principle of a hardness test.

Hardness tests use indenters shaped as pyramids and balls to press, hit or scratch objects in order to cause deformation. We will then judge the objects as being harder when the deformations are smaller. Modern hardness testing began with the Brinell hardness test. A hardened steel ball is pressed to damage the sample. This test was developed because the hardness of mass-produced gears needed to be controlled. As the tests needed to be performed on every part rather than on a sample, the parts had to be usable after testing. Therefore damage to the parts had to be minimal such that it is negligible.

Simply put, hardness is the resistance to deformation upon indentation.

Sample of a hardness test block

Types of hardness testing

Hardness tests can be categorized into three classes based on the damage caused to the sample:

Indentation hardness test

a) Brinell Hardness Test

Characteristics

Brinell hardness HB is determined from the applied load and the area of the resulting indentation as stress on the indented surface, while pressing a ball on the sample surface.

Brinell Hardness Testers

Test Instrument

Brinell hardness testers can apply up to 3,000 kgf of compressive load.

Indenter

The standard indenter for Brinell hardness test is a 10 mm hardened steel ball. There are other options for smaller diameters to make smaller indentations: 5 mm, 2 mm, 1 mm. While the indenter material is mainly hardened steel, it can only be used up to HB 350. This is due to hard samples imparting plastic deformation to it. Hence, for harder samples, cemented carbides are used. They can go up to HB 650.

b) Vickers Hardness Test

Characteristics

Vickers hardness is calculated from the indentation load and indentation surface area while pressing a square-based pyramidal indenter on the sample surface.

Vickers Hardness Testers

Test Instrument

Using one end of the loading lever as a point of support, hang a counterweight on the other end and place a spindle near the point of support with the indenter attached. The indenting rate is adjusted using a cam or a dashpot. In microhardness testers with light loads, the load is applied directly on the indenter.

Indenter

The indenter is a diamond having square pyramid shape with an angle of 136° between the opposite faces.

c) Knoop Hardness Test

Characteristics

Knoop hardness is determined using asymmetric pyramidal indenters which enable measurements of thin surface layers and fine sheets.

Brinell & Rockwell Testers with Knoop scale available

Test Instrument

Micro-Vickers hardness tester is used with a Knoop indenter attached.

Indenter

The indenter is a square pyramid diamond, with the vertex angles of 170°30′ and 130° and rhombus-shaped cross sections.

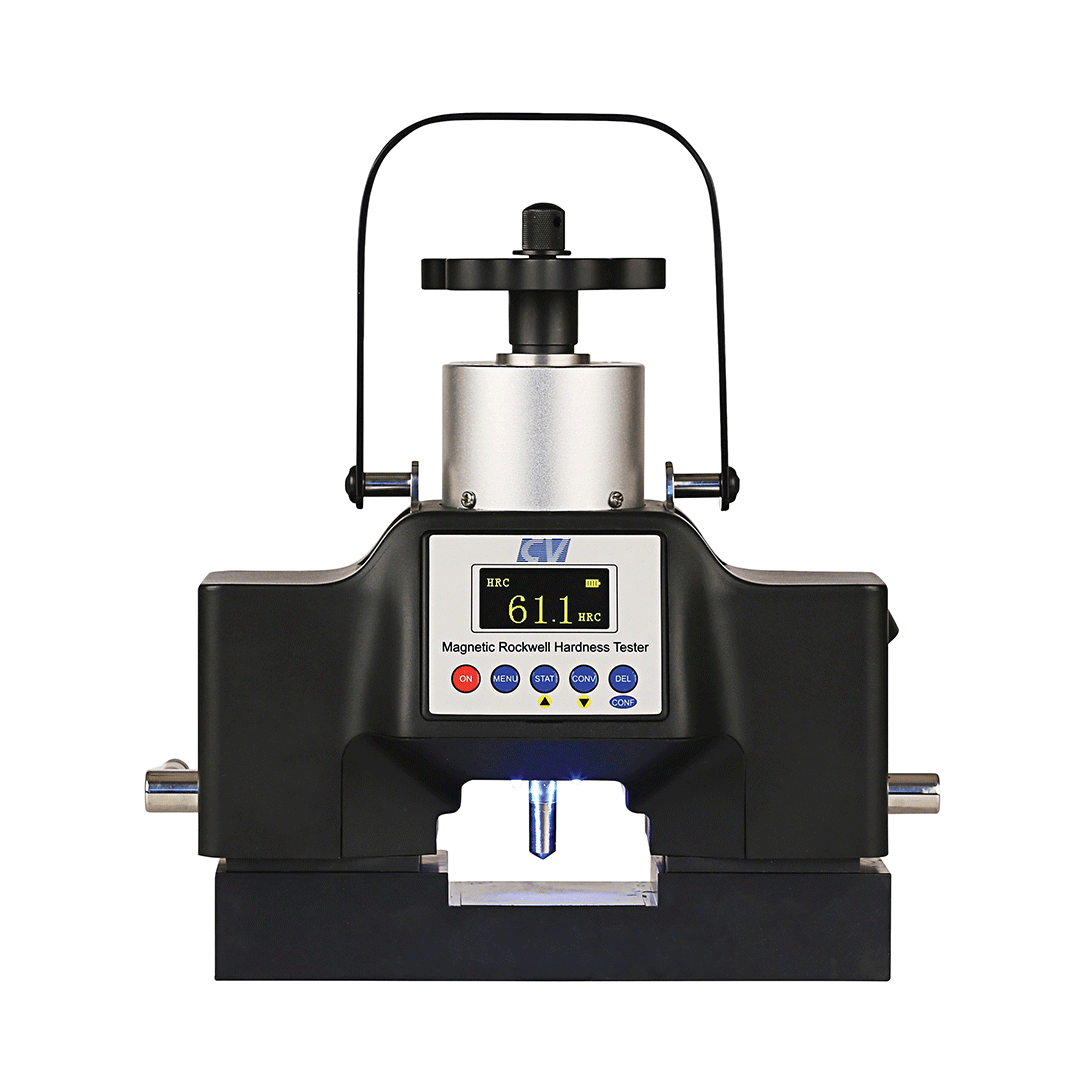

d) Rockwell Hardness Test

Characteristics

Rockwell hardness test is the most commonly used test in manufacturing. We begin by pressing the indenter into the sample surface with a reference load. After which we apple a test load, and return to the reference load. Penetration depth is then measured using a dial gauge when the load is returned to the reference load. The measurement is fast and suitable for work sites.

Rockwell Hardness Testers

Test Instrument

The load is changed as a reference load, test load and thereafter reference load. A reference load of 10 kgf is applied using a spring. Test loads (150 kgf, 100 kgf, 60 kgf) are applied with a spindle. Motion in the direction of the indentation is measured using a dial gauge.

Indenter

There are 2 indenter types, diamond and ball indenter. The diamond indenter is a cone with the apex angle of 120°, and the tip is a spherical surface of 0.2 mm in radius. The ball indenter has a diameter of 1.5875 mm (1/16 in) or 3.175 mm (1/8 in) and is made of steel or cemented carbide.

Rebound Hardness Test

Shore Hardness Test

Characteristics

This test drops a hammer with an indenter attached, and measures the hardness from the rebound height after the hammer hits the sample surface. The test equipment is inexpensive, and the method is simple. It is conveniently used for hardness measurements of large parts and rolling mill rolls.

As hardness is measured from the energy expended in making an indentation through the hammer’s collision with the sample surface, the sample deformation is the same as in indentation hardness tests, but the deformation rate is high.

Shore Hardness Tester

Test Instrument

Type C: The hammer is dropped inside a glass tube, and the rebound height is measured by eye.

Type D: The rebound height of the hammer is measured using a dial gauge. It is easier to handle than type C.

There are many type of shore hardness testers also known as Durometers (image shown above). This can be used to measure shore hardness value of plastics and rubber.

Indenter

A diamond indenter is attached at the tip of a cylindrical hammer. The tip is polished to adjust the radius of curvature so that it is as hard as the standard sample. With a small radius of curvature, the rebound height becomes small. The standard sample is controlled using Vickers hardness. The hardness is verified against the standard sample. If there is a mismatch, the indenter shape is corrected.

To read more about Shore Hardness Testers, click here to read our blog post "Basics of Durometers".

Scratch Hardness test

a) Martens hardness

In this type of test, the surfaces are scored with a diamond cone driven by a fixed force, making it suitable for more resistant substances. The hardness of materials is calculated by measuring the width of the scratch produced by the point of the diamond.

b) Bierbaum hardness

A blunt element (usually diamond) is moved across the surface of the workpiece being tested under controlled conditions of load and shape. The width of the groove is the measure of hardness.

If you are looking for any hardness testers or hardness test blocks, feel free to contact us for a consultation.

References:

1. Nakamura, M. (2019). Theory and Application of Hardness Tests. Yamamoto Scientific Tool Laboratory Co., Ltd.

2. Research, I. (2020, December 28). Tests of Hardness of Materials. Retrieved April 06, 2021, from https://www.infinitiaresearch.com/en/news/tests-of-hardness-of-materials/#Martens_hardness_test

3. Chandler, H. (1999). Hardness Testing, 2nd Edition, ASM International. www.asminternational.org