What is a Durometer?

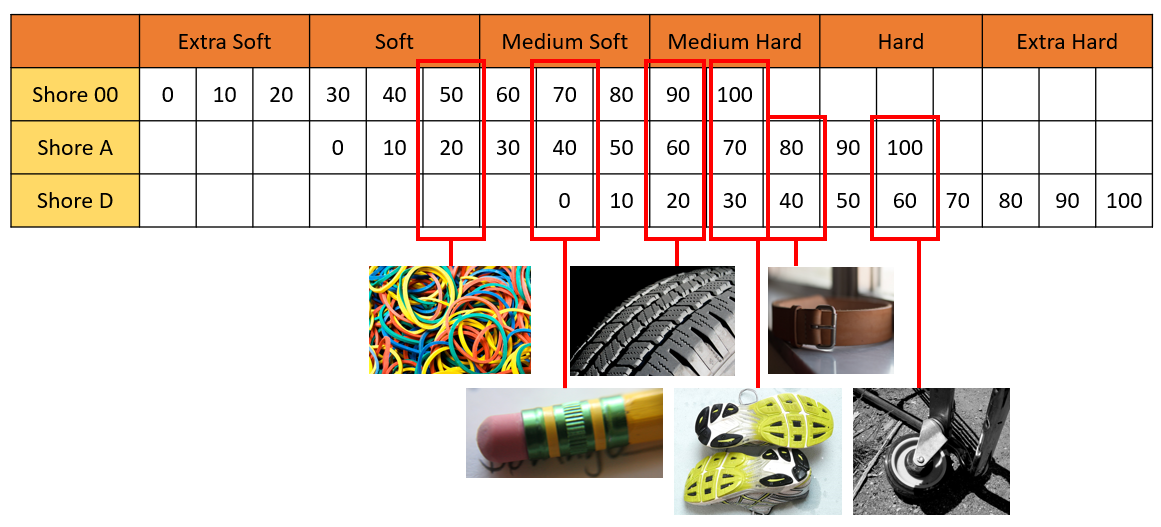

A durometer is a type of hardness testing device that follows a Shore scale to measure and determine the hardness of a material. Depending on the material, different Shore scales can be used, with Shore 00, Shore A and Shore D being the most common out of the 12 scales. Of the three, the Shore 00 scale caters to rubbers and gels that are extremely soft. The Shore A scale is meant for materials that are slightly harder and covers a wide variety such as mold rubbers that can range from very soft and flexible to somewhat flexible and even up to semi-rigid plastics. On the other hand, the Shore D scale allows for testing on even harder materials like hard rubbers, semi-rigid plastics and hard plastics.

Which scale should I use?

Each of these scales are measured from a range of 0 to 100, with higher values indicating a harder material tested. Durometers rate materials on this scale in increments of 10 and come with an acceptable tolerance range of plus or minus 5 points. A durometer score of Shore 70A is the most common when it comes to picking an acceptable standard of hardness.

As a reference, here are some materials and their shore hardness:

To ensure that the right scale is chosen, readings that are less than 10 or more than 90 should be rejected as this would indicate that another scale may be more appropriate. For example, a Shore A rating of 95 would prompt users to use the Shore D scale instead as the material is of a harder nature and cannot be captured precisely with the Shore A scale. The opposite should also happen when the score is Shore 5A to prompt users to use the Shore 00 scale instead of softer rubbers and gels.

How does it work?

To measure the hardness of rubbers and plastics, a needle attached to the durometer will be placed against the material. Pressure is then applied to the durometer for the needle to press firmly perpendicularly into the material and the reading taken will indicate the hardness measured for the material. Sufficient force has to be applied to the durometer to ensure that readings taken are as precise as can be. Shore A durometers would require less force at 0.822kg while a Shore D durometer would require a higher force of 4.55kg. This is because materials measured with Shore D durometers are of a harder nature and thus would require more force to be applied to take accurate readings. Regardless of the type of durometer scale, even pressure should also be applied for 15 seconds.

It is very important to ensure that the material tested has a flat surface because hardness readings with a durometer will not be accurate if it were done on surfaces that are round, rough or uneven. The sample of material tested should also be at least 19mm by 44mm in size with a thickness of 6mm. Several thin layers of the material may be layered to achieve the 6mm thickness requirement but care must be taken to avoid air from being trapped between layers. An average of 5 readings should also be taken, each at least 13mm from the edges and 6mm apart from one another to ensure fair and uninterrupted readings.

Uses for a Durometer

As a mold maker, a durometer is one of the most useful tools that one can use to determine the material used for the mold cast. Depending on how intricate the design of the object to be casted, the flexibility of the mold rubber will be determined. Objects that are more complicated features or many protruding and extending arms would require a mold with more flex that will allow for easy removal after it has been casted.

As such, a Shore 30A durometer rubber would be more suitable than a Shore 70A durometer rubber that is firmer and is less flexible. Instead, a Shore 70 durometer rubber is more suitable for making molds of flat objects with an even surface like tiles and paving stones. These objects require less flexibility in their molds as they can be easily removed.

Durometers are also critical when it comes to choosing the type of silicone rubber for use in heat sealing packaging applications. High temperature heat sealing silicone rubber that has a Shore 70A to Shore 90A score is recommended for use on the side that comes into contact with the heating tools. As compared to silicone rubbers that have a lower durometer score, a Shore 70A durometer rubber is able to provide better heat transfer which translates to more efficient heat sealing.

DeFelsko PosiTector SHD Digital Durometer

DeFelsko PosiTector SHD Digital Durometer is optimized to measure hardness in hard polymers, elastomers, and rubbers. The probe body itself is made of hardened steel with the indenter pin needle made of stainless steel, making it highly versatile to test various hard materials. There are two models of probe to choose from, Shore A and Shore D that cater to specifically measuring materials of different properties.

The pin shaped needle is particularly useful in quality testing of pneumatic marine fenders, rubbery buoy belt, leather, rubber hose, insulation damper, kevlar vest and many more. The device conforms with ASTM D2240, D2240, ISO 868/7267/7619 and DIN 53505, and comes with an accuracy of ≤ ±1 HA/HD with a 0.1HA/HD resolution.

Although durometers are important in the decision making process to select the best material for each job, it should not be the only point of comparison as it cannot measure all aspects that determine a material’s lifespan. For example, a durometer score will not be able to measure how resistant a piece of plastic is to scratches and abrasions as the hardness of the plastic or rubber is relative to other plastics and rubbers on the same scale and not across all scales.

If you wish to find out more about Durometers, feel free to contact us for a consultation.

Click here to read more about the various types of hardness testing in our blog post "What is Hardness Testing?"

References

- Shore durometer - Wikipedia. Retrieved 8 July 2021, from https://en.wikipedia.org/wiki/Shore_durometer

- Silicone rubber - Wikipedia. Retrieved 8 July 2021, from https://en.wikipedia.org/wiki/Silicone_rubber

- Polymer - Wikipedia. Retrieved 8 July 2021, from https://en.wikipedia.org/wiki/Polymer

- Elastomer - Wikipedia. Retrieved 8 July 2021, from https://en.wikipedia.org/wiki/Elastomer