Untuk mendapatkan informasi lebih lengkap tentang:

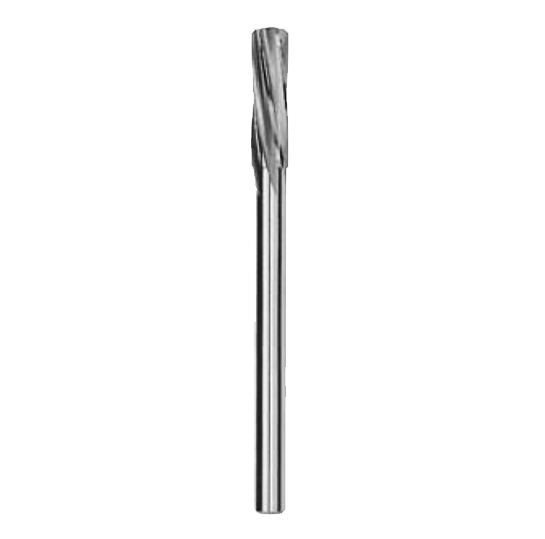

Widia Cermet-Tipped Reaming Tools CERMET-DCFD™ Series

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

HSR • HSR • High Speed Reamers for Through and Blind Holes • 14mm - 20mm (.551" - .787") • Coated DCFD • "A" Shank

Widia Solid Carbide Reaming Tools HSR™ Series has been designed to give fabricator a platform to covers the majority of hole finishing needs, with diameters up to 20mm and a range of edge preps and geometries available. The classic design of four to eight flutes are individually brazed carbide tips without any coating. The HSR series provides high consistency and excellent grip to thermal effects during machining operations.

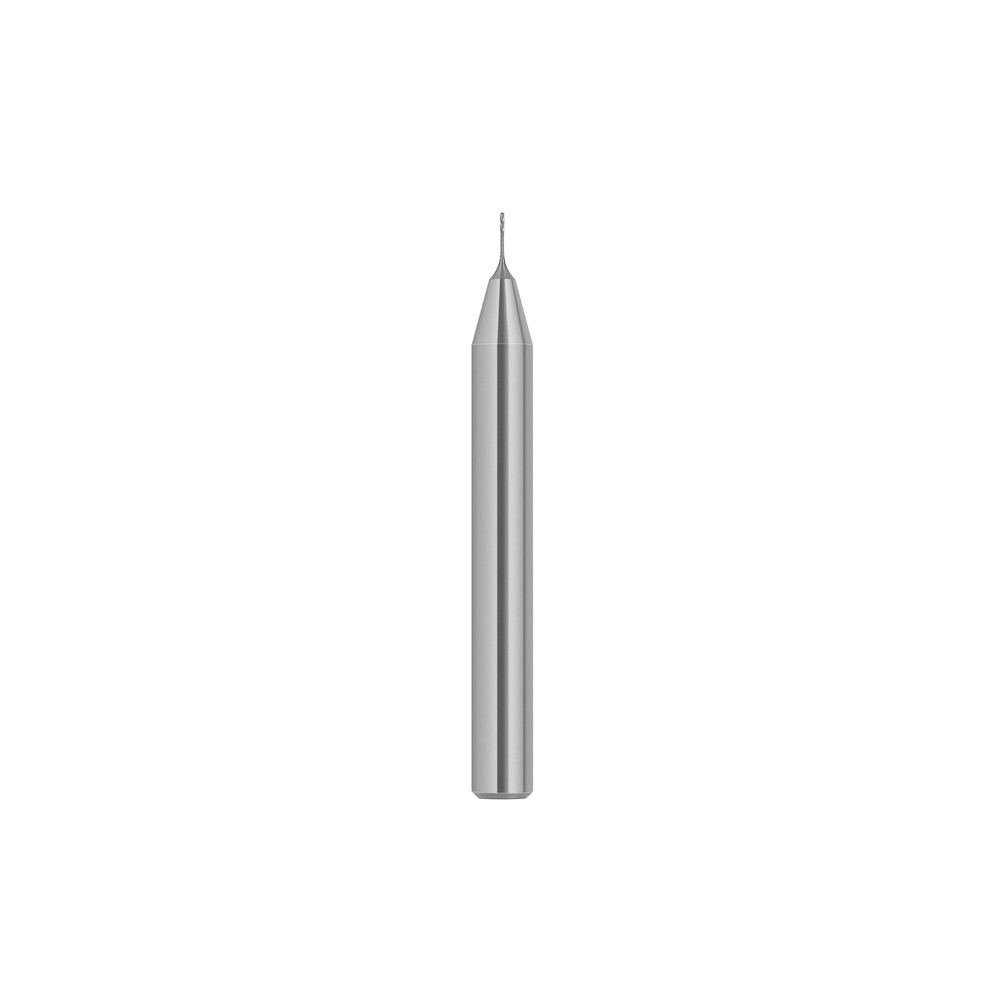

Widia CERMET-DCFD™ is devised with cermet coated tip, which is engineered to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. Elements used in Widia CERMET-DCFD™ reamer series are patented combination of nickel, molybdenum, and cobalt (TiC / Titanium Carbide and TiN / Titanium Nitride). This clever ingredients provide much economical life in cutting tough metals where built-up edge is a problem. With brazing and grinding qualities like tungsten carbide, its self-sharpening wear pattern keeps cutting forces low even after long periods in cut. Furthermore in finishing, you can have a close tolerances with smooth and fine polished surfaces.

For bigger diameter upto 42mm, you can also opt for Widia Top Ream platform in class carbide. WIDIA’s WU05PR advanced reaming grade was developed specifically for the demanding tool wear and surface finish requirements encountered in most hole reaming operations. For example, tests performed over a total cut distance of 30m in length showed an ability to consistently maintain surface finishes of 0.8μm in 4140 steel alloy and 1.6μm in gray cast iron, three times that of TiAlN-coated tools which are desired in mould making, mechatronics parts, micro machining in aerospace industry and many more.

Widia Cermet-Tipped Reaming Tools HSR™ Series Feature:

- The finest tool for reaming and finishing in stainless steels, nodular cast irons, low carbon steels and ferritic steels and all ferrous materials.

- Helical flute for reaming through and cross hole with through coolant application

- Designed with Straight Flutes for Blind Holes • K10F™/K10F-DCFD™ • 14–32mm

- Their reinforced shank offers a greater stability necessary to these high precision tools especially on fully CNC operation.

- Standard reamers listed are ground to achieve an H7 tolerance hole. IT6 capability is available. Additional diameters and lengths made to order.

- Complete Widia PDF catalog on metric can be downloaded here and on inches here (103 MB)

SPESIFIKASI Widia Cermet-Tipped Reaming Tools CERMET-DCFD™ Series

Widia Solid Carbide Reaming Tools HSR™ Series Ordering Guide :

| order number | CERMETDCFD | D1 | D | L | L4 | L10 | LS | Z |

|---|---|---|---|---|---|---|---|---|

| 3888407 | 456680-001400 | 14,00 | 16,00 | 145 | 76 | 8 | 49 | 6 |

| 3888408 | 456680-001500 | 15,00 | 16,00 | 145 | 76 | 8 | 49 | 6 |

| 3888409 | 456680-001600 | 16,00 | 20,00 | 157 | 86 | 8 | 51 | 6 |

| 3888410 | 456680-001700 | 17,00 | 20,00 | 157 | 86 | 10 | 51 | 6 |

| 3888411 | 456680-001800 | 18,00 | 20,00 | 171 | 100 | 10 | 51 | 6 |

| 3888412 | 456680-001900 | 19,00 | 20,00 | 171 | 100 | 10 | 51 | 6 |

| 3888413 | 456680-002000 | 20,00 | 20,00 | 200 | 129 | 10 | 51 | 6 |

The above dimensions are used when ordering custom solution reamers on this page unless otherwise specified.

Please see pages [REFERENCE] and [REFERENCE] for information on ordering custom solutions.

| D1min | D1max | D | L | L4 | L10 | LS | Z |

|---|---|---|---|---|---|---|---|

| 14,00 | 15,99 | 16,00 | 145 | 97 | 9 | 48 | 6 |

| 16,00 | 17,99 | 20,00 | 157 | 107 | 9 | 50 | 6 |

| 18,00 | 19,99 | 20,00 | 171 | 121 | 9 | 50 | 6 |

| 20,00 | 21,99 | 20,00 | 200 | 150 | 9 | 50 | 6 |

| 22,00 | 25,99 | 20,00 | 210 | 160 | 11 | 50 | 6 |

| 26,00 | 29,99 | 25,00 | 240 | 184 | 11 | 56 | 8 |

| 30,00 | 32,00 | 25,00 | 270 | 214 | 11 | 56 | 8 |

Harga Widia Cermet-Tipped Reaming Tools CERMET-DCFD™ Series

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.