Untuk mendapatkan informasi lebih lengkap tentang:

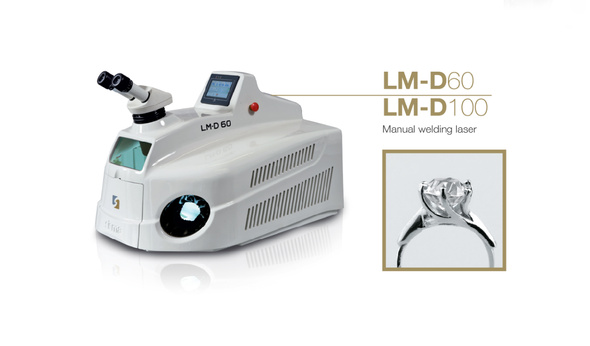

Sisma Welding Laser LM-D Manual Series

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

The Sisma LM-D Manual Laser Welding System is a versatile and precise tool designed for welding applications in various industries. This compact and user-friendly system offers exceptional control and accuracy, making it ideal for both delicate and robust welding tasks. With its intuitive interface and adjustable parameters, operators can achieve pinpoint accuracy and high-quality welds. The Sisma LM-D is a reliable solution for jewelry, dental, automotive, and electronics manufacturing, providing efficient and consistent results for your welding needs. Whether you're working on intricate designs or large-scale projects, this manual laser welding system empowers you to achieve flawless welds with ease. Experience the future of welding technology with the Sisma LM-D.

The machine is touted as a high precision Nd:YAG welding system without forgetting the practicality, low maintenance for long term use and durability without additional cost on consumables. Sisma LM-D Manual Welding Laser allows you to achieve precise welding finish which needs minimal abrasive process with seamless result. For additional power, you can also feed argon gas directly to the welding point for better execution.

Sisma LM-D Manual Welding Laser works by utilizing Fiber Ytterbium (Yag) laser beam which emit light with a wavelength of 1064µm (10x smaller diameter compared to Co2 marking laser). Compared to regular Co2 based laser machine, Sisma's YAG laser technology produce world's highest accuracy which comes without the need for regular head source maintenance, optical replacement, Co2 gas nozzle consumables, pressure gauges and excessive fire retardant kit which usually needed when working with Co2 laser machine. You can also equip Argon gas as inert shielding gas in performing rapid pulse on high-temperature industrial welding processes where ordinarily unreactive substances become reactive. This high efficiency laser will give you better operating costs and a much safer working environment with a user-friendly format.

Sisma LM-D manual welding laser is the ideal investment for industrial electronics welding, fabrication of jewelry, fabrication of medical equipment, sensors fabrication and electronics due to fast material processing, precise beam size, excellent pulse-to-pulse stability and contactless operation. Sisma LM-D manual welding laser are designed with a soft and attractive design for safety concern.

Why Choose the Sisma LM-D Manual Laser Welding?

- Stability - The machine is equipped with Smart Spot technology to ensure high repeatability in your welding process. It has a wide depth of field and fires a stable laser even from the first pulse.

- Comfort - Ergonomics was considered when designing the LM-D. It is further accentuated by the low noise production to prioritize the comfort of the user. The machine also comes with an ECO function, which deactivates certain system components when the machine is inactive. This provides energy saving in terms of reduced consumption.

- Connectivity - The machine by default has USB and ethernet ports built in. This was done for ease of downloading, uploading welding parameters. The ports can also be used for software and firmware updates. The machine can also be controlled remotely with a smart phone, table and computer.

Features:

- Absolute guarantee of stability laser beam alignment.

- Pulsated laser beam with user friendly controller

- Leica microscope with proper shielding and optical-digital magnification

- Ease of maintenance (without opening the box) through a rear door access to the easy replacement of water filter and deionizing filter. Controlling the level of water and any addition is always done through the rear door.

- Colour touch-screen display for convenient set up.

- 250 storage places for parameters.

- It can be enforced with low pressure Argon gas as the shielding gas for higher thermal welding.

- Supplied with gas protection and regulator of the cooling air.

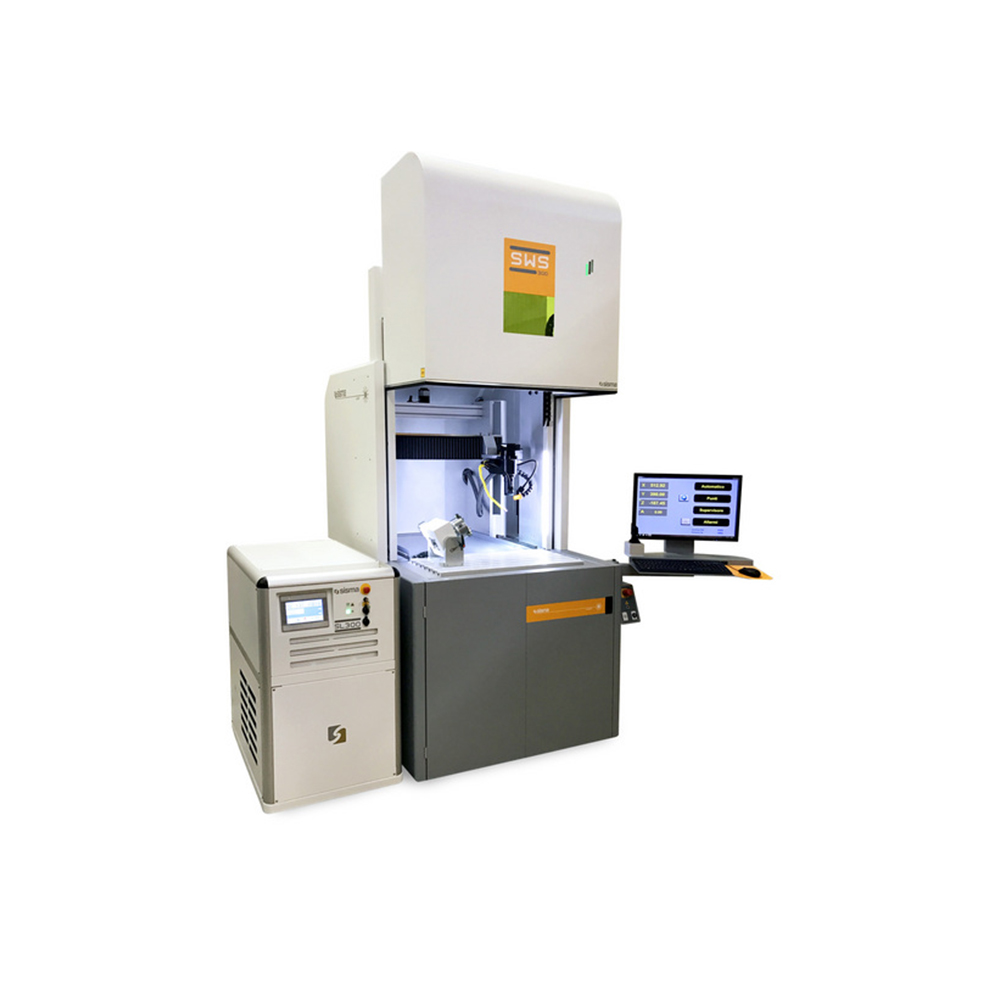

- Can be equipped with XYZ 3 axis rotation table with joystick controller

- Deionizing filter supplied as standard.

- 24-month warranty (flash lamp included).

SPESIFIKASI Sisma Welding Laser LM-D Manual Series

Sisma LM-D manual welding laser Ordering Guide:

|

|

LM-D 60 | LM-D 100 |

| Power supply | 200 - 240V 50/60 Hz 10 A | 200 - 240V 50/60 Hz 10 A |

| Average power | 60 W | 80 W |

| Peak pulse power | 7.5 KW | 9 KW |

| Pulse energy | 60 J | 100 J |

| Pulse duration | 0.3 - 30 ms | 0.3 - 30 ms |

| Pulse frequency | 0 - 20 Hz | 0 - 20 Hz |

| Welding spot diameter | 0.2 - 2 mm | 0.2 - 2 mm |

| Focus adjustment | Motorized | Motorized |

| Pulse shape | 7 pre-set | 7 pre-set |

| Programming memory | Up to 250 | Up to 250 |

| Stereo microscope | LEICA | LEICA |

| Chamber illumination | LED | LED |

| Cooling | Water / air | Water / air |

| Fume extraction | Integrated | Integrated |

| Dimensions | 540 x 690 x 460 mm | 540 x 690 x 460 mm |

| Net weight | 50 Kg | 50 Kg |

Harga Sisma Welding Laser LM-D Manual Series

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.