Untuk mendapatkan informasi lebih lengkap tentang:

Chennai Metco Spectro Grinder Bainline VSG

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Heavy Duty Spectro Grinder – Variable Speed

In metallography process, the next step after the specimen is fitted and properly sized (with any Chennai Metco BAINCUT models) will be preparing the coarse surface of the specimen. Hence, to flatten the coarse specimen of larger size and tougher metal such as titanium to the finest surface, Chennai Metco BAINLINE VSG is the answer. The specimens to be ground in 60, 80 or 120 grit after cutting or moulding operation to remove surface imperfections. Useful step to remove light metallurgical damage in the specimen surface induced during cut-off operation.

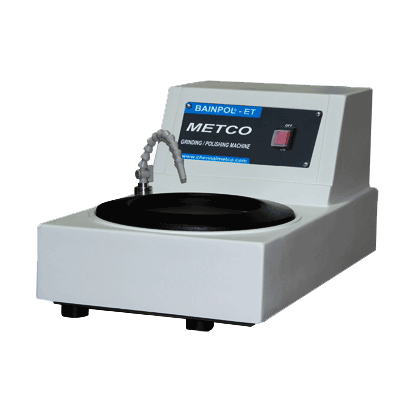

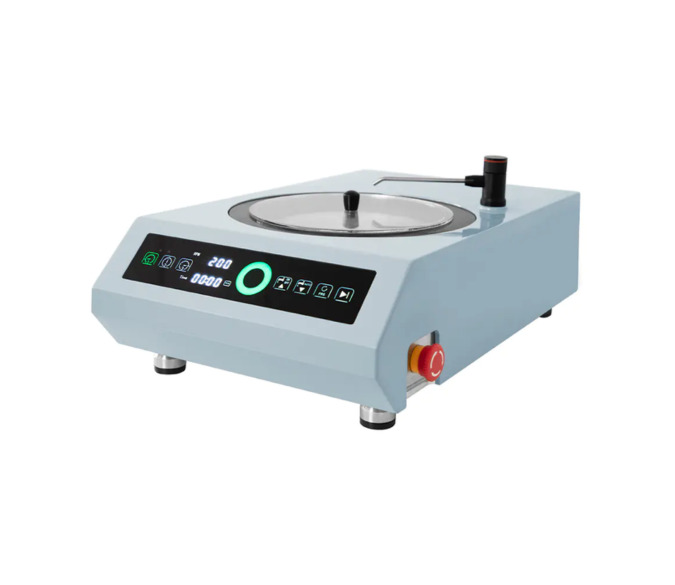

After the specimen is fine enough, the next step will be using the Chennai Metco BAINPOL VTD for variable speed Polisher / Grinder of specimen (which can be operated and polished freehand). BAINPOL VTD works to grind and polish finer abrasive particles until the desired surface quality is ready for chemical etching so that that the metallographic structure of specimen can be observed in detail with Vision engineering TIM5 or digital, optical, or electron microscopy.

SPESIFIKASI Chennai Metco Spectro Grinder Bainline VSG

Chennai Metco belt grinder features:

1/2HP single phase motor, 1440 RPM

100mm x 915mm Endless belt

Aluminium idler pulley machanism

Easy removable dust cover system

Easy belt change mechanism

Dust receiver

Size : 560 x 350 x 250 mm

Harga Chennai Metco Spectro Grinder Bainline VSG

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.