Untuk mendapatkan informasi lebih lengkap tentang:

Behringer Automatic Plate Bandsaw Machine VPS Series

Segera Hubungi Kami :

(62) 778 408 6403

(62) 815 3611 0114

sales@lfc.co.id

Behringer Automatic Plate Bandsaw Machine VPS Series Efisiensi tertinggi dalam pemotongan silang slabs dan plates Behringer Automatic Plate Bandsaw Machine VPS Series adalah solusi Behringer untuk pemotongan silang sepenuhnya otomatis dari slabs besar dan plates. Penempatan vertikal dari bandsaw memiliki keunggulan yang jelas dibandingkan desain horizontal, karena panjang pengikatan bandsaw jauh lebih pendek. Peningkatan kinerja pemotongan yang signifikan dengan pengurangan biaya alat, sudah cukup memberikan bukti yang jelas. Dengan desain yang kokoh dan komponen berperforma tinggi, mesin bandsaw seri VPS dirancang untuk aplikasi yang menuntut di perdagangan baja, industri dan produksi logam. Mulai dari logam non-besi dan aluminium hingga baja kerja sederhana dan material yang sulit untuk dikerjakan dengan mesin seperti Inconel atau titanium. Desain modularnya memungkinkan mesin bandsaw untuk disesuaikan secara individual dengan aplikasi pelanggan. Berikut adalah beberapa fitur Behringer Automatic Plate Bandsaw Machine VPS Series, antara lain: Sistem Servo Feed Sistem pengumpanan servo Behringer memastikan penghilangan chip yang konstan dan memanfaatkan kemampuan pisau bandsaw modern dengan lebih baik. Respon cepat dari sistem pengumpanan servo ke sensor untuk pengaturan tekanan pemotongan secara sistematis mencegah kelebihan beban dan keausan dini pada pisau bandsaw. Feeding Gripper yang Digerakkan oleh Servo Dengan posisi rahang tetap yang bergerak linier memposisikan material dengan andal dan presisi. Gripper ini memiliki desain terpisah untuk menampung plate lebar dan diposisikan melalui dua penggerak spindle yang terhubung secara elektronik. Performa Presisi & Pemotongan Tak Tertandingi Akurasi pemotongan yang tinggi, pengoperasian yang tenang, dan masa pakai pisau yang lama semuanya berasal dari desain kerangka gergaji yang tahan torsion khusus. Dibandingkan dengan mesin gergaji plat dan blok dari produsen lain, gaya untuk umpan gergaji diterapkan langsung di bawah titik pemotongan, yang menghasilkan gerakan umpan yang lebih akurat. Sistem Kontrol Cerdas Pengoperasian semua fungsi secara cepat dan mudah melalui kontrol sentuh. Konveyor Serpihan yang Efisien Konveyor serpihan yang ukurannya besar dengan tangki pendingin terintegrasi terletak di bawah unit gergaji, tepat di arah aliran serpihan. Setiap serpihan dan cairan pendingin dikumpulkan dan dipisahkan di sini. Konveyor dapat digerakkan keluar dari bingkai mesin untuk membersihkan dan perawatan. Dukungan Material Dilengkapi Penutup dengan Aksesibilitas Optimal Behringer sangat memperhatikan aspek pemeliharaan dan perawatan mesin: semua suku cadang dan komponen penting sangat mudah dijangkau. Desain terbuka menawarkan akses langsung ke semua suku cadang yang aus, mengoptimalkan pemeliharaan dan perbaikan serta menyederhanakan pergantian pisau gergaji. Fitur Lainnya: Pengaturan Vertikal pada Bandsaw Mengurangi panjang pengikatan saat memotong lempengan dan plate yang lebar. Dibandingkan dengan bandsaw horizontal, dapat digunakan pisau bandsaw yang lebih kecil dan lebih halus. Hal ini meningkatkan kinerja pemotongan, menurunkan biaya alat, dan mengurangi jumlah material terbuang (kerf). Unit Pemotongan yang Memiliki Performa Tinggi Dalam desain rangka C yang tahan terhadap torsion menjadi inti dari sistem. Pemanduan langsung dari bingkai pemotong yang dekat dengan area kerja memungkinkan kinerja pemotongan yang lebih baik dan getaran yang rendah. Cast Iron Band Guiding Parts Diproduksi oleh Behringer yang memberikan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat. Sikat Chip Dupleks Bertenaga Secara aktif membersihkan pisau dan mencegah serpihan tertarik ke dalam saluran pemotongan. Sikat-sikat ini disesuaikan secara otomatis ke arah pisau gergaji, memastikan tindakan pembersihan yang merata. Manfaatnya: Umur alat yang lebih panjang dan kerusakan sikat yang lebih rendah. Lengan Pemandu Otomatis Menghasilkan pemotongan terbaik tanpa penyesuaian - bahkan dengan ukuran material yang sering berubah. Penggunaan Pisau Gergaji Karbida yang Ekonomis Karena desain yang kokoh, penggunaan teknologi servo terbaru, dan pembuangan serpihan yang berdimensi baik. LFC adalah distributor eksklusif untuk Behringer Automatic Plate Bandsaw Machine VPS Series di Singapura dan Malaysia. Behringer Automatic Plate Bandsaw Machine VPS Series dapat dikonfigurasi dengan sempurna sesuai dengan kebutuhan Anda dengan berbagai opsi. Inilah cara untuk mendapatkan hasil terbaik dari produksi Anda. Tim kami akan senang untuk memberi saran kepada Anda. Hubungi kami untuk diskusi!

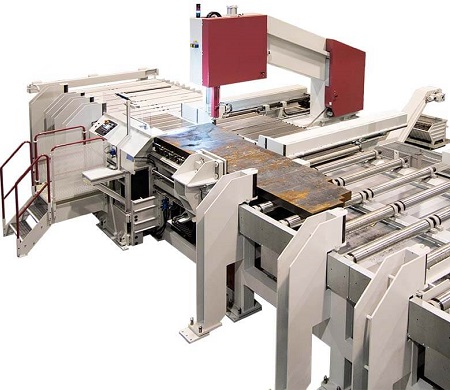

Behringer Automatic Plate Bandsaw Machine VPS Series

Efisiensi tertinggi dalam pemotongan silang slabs dan plates

Behringer Automatic Plate Bandsaw Machine VPS Series adalah solusi Behringer untuk pemotongan silang sepenuhnya otomatis dari slabs besar dan plates. Penempatan vertikal dari bandsaw memiliki keunggulan yang jelas dibandingkan desain horizontal, karena panjang pengikatan bandsaw jauh lebih pendek. Peningkatan kinerja pemotongan yang signifikan dengan pengurangan biaya alat, sudah cukup memberikan bukti yang jelas.

Dengan desain yang kokoh dan komponen berperforma tinggi, mesin bandsaw seri VPS dirancang untuk aplikasi yang menuntut di perdagangan baja, industri dan produksi logam. Mulai dari logam non-besi dan aluminium hingga baja kerja sederhana dan material yang sulit untuk dikerjakan dengan mesin seperti Inconel atau titanium. Desain modularnya memungkinkan mesin bandsaw untuk disesuaikan secara individual dengan aplikasi pelanggan.

Berikut adalah beberapa fitur Behringer Automatic Plate Bandsaw Machine VPS Series, antara lain:

|

Sistem Servo Feed Sistem pengumpanan servo Behringer memastikan penghilangan chip yang konstan dan memanfaatkan kemampuan pisau bandsaw modern dengan lebih baik. Respon cepat dari sistem pengumpanan servo ke sensor untuk pengaturan tekanan pemotongan secara sistematis mencegah kelebihan beban dan keausan dini pada pisau bandsaw. |

|

|

Feeding Gripper yang Digerakkan oleh Servo Dengan posisi rahang tetap yang bergerak linier memposisikan material dengan andal dan presisi. Gripper ini memiliki desain terpisah untuk menampung plate lebar dan diposisikan melalui dua penggerak spindle yang terhubung secara elektronik. |

|

Performa Presisi & Pemotongan Tak Tertandingi Akurasi pemotongan yang tinggi, pengoperasian yang tenang, dan masa pakai pisau yang lama semuanya berasal dari desain kerangka gergaji yang tahan torsion khusus. Dibandingkan dengan mesin gergaji plat dan blok dari produsen lain, gaya untuk umpan gergaji diterapkan langsung di bawah titik pemotongan, yang menghasilkan gerakan umpan yang lebih akurat. |

|

|

Sistem Kontrol Cerdas Pengoperasian semua fungsi secara cepat dan mudah melalui kontrol sentuh. |

|

Konveyor Serpihan yang Efisien Konveyor serpihan yang ukurannya besar dengan tangki pendingin terintegrasi terletak di bawah unit gergaji, tepat di arah aliran serpihan. Setiap serpihan dan cairan pendingin dikumpulkan dan dipisahkan di sini. Konveyor dapat digerakkan keluar dari bingkai mesin untuk membersihkan dan perawatan. |

|

|

Dukungan Material Dilengkapi Penutup dengan Aksesibilitas Optimal Behringer sangat memperhatikan aspek pemeliharaan dan perawatan mesin: semua suku cadang dan komponen penting sangat mudah dijangkau. Desain terbuka menawarkan akses langsung ke semua suku cadang yang aus, mengoptimalkan pemeliharaan dan perbaikan serta menyederhanakan pergantian pisau gergaji. |

Fitur Lainnya:

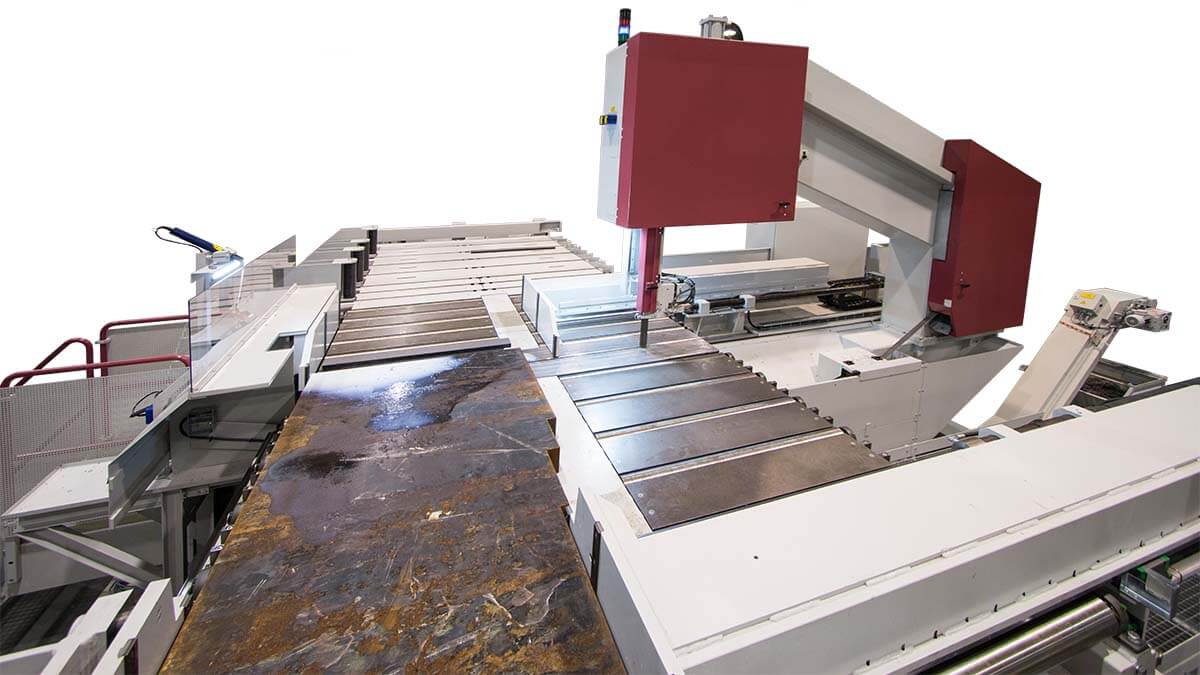

Pengaturan Vertikal pada Bandsaw

Mengurangi panjang pengikatan saat memotong lempengan dan plate yang lebar. Dibandingkan dengan bandsaw horizontal, dapat digunakan pisau bandsaw yang lebih kecil dan lebih halus. Hal ini meningkatkan kinerja pemotongan, menurunkan biaya alat, dan mengurangi jumlah material terbuang (kerf).

Unit Pemotongan yang Memiliki Performa Tinggi

Dalam desain rangka C yang tahan terhadap torsion menjadi inti dari sistem. Pemanduan langsung dari bingkai pemotong yang dekat dengan area kerja memungkinkan kinerja pemotongan yang lebih baik dan getaran yang rendah.

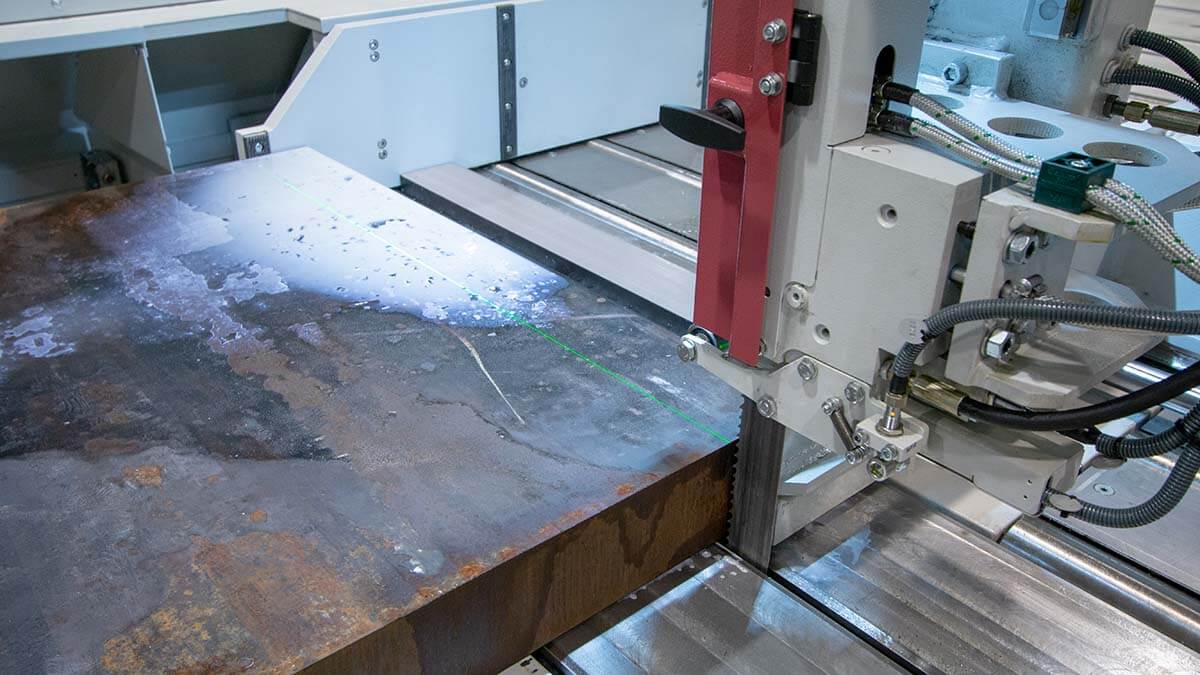

Cast Iron Band Guiding Parts

Diproduksi oleh Behringer yang memberikan efek peredam getaran. Ini secara langsung mengurangi getaran di tepi tempat bahan dipotong, sehingga masa pakai alat pisau bandsaw meningkat.

Sikat Chip Dupleks Bertenaga

Secara aktif membersihkan pisau dan mencegah serpihan tertarik ke dalam saluran pemotongan. Sikat-sikat ini disesuaikan secara otomatis ke arah pisau gergaji, memastikan tindakan pembersihan yang merata. Manfaatnya: Umur alat yang lebih panjang dan kerusakan sikat yang lebih rendah.

Lengan Pemandu Otomatis

Menghasilkan pemotongan terbaik tanpa penyesuaian - bahkan dengan ukuran material yang sering berubah.

Penggunaan Pisau Gergaji Karbida yang Ekonomis

Karena desain yang kokoh, penggunaan teknologi servo terbaru, dan pembuangan serpihan yang berdimensi baik.

LFC adalah distributor eksklusif untuk Behringer Automatic Plate Bandsaw Machine VPS Series di Singapura dan Malaysia. Behringer Automatic Plate Bandsaw Machine VPS Series dapat dikonfigurasi dengan sempurna sesuai dengan kebutuhan Anda dengan berbagai opsi. Inilah cara untuk mendapatkan hasil terbaik dari produksi Anda. Tim kami akan senang untuk memberi saran kepada Anda. Hubungi kami untuk diskusi!

SPESIFIKASI Behringer Automatic Plate Bandsaw Machine VPS Series

| Cutting Range | VPS60-160A | VPS60-200A | VPS60-220A |

| Cutting range flat W x H | 1,600 x 600 mm | 2,000 x 600 mm | 2,200 x 600 mm |

| Smallest dimension to be sawn flat W x H | 500 x 20 mm | ||

| Shortest cutting length | 15 mm | ||

| Performance Characteristics | VPS60-160A | VPS60-200A | VPS60-220A |

| Feeding length single stroke | 1,500 mm | ||

| Drive Power | 7.5 kW | ||

| Blade speed | 17-120 m/min | ||

| Saw blade dimensions | 10,070 x 54 x 1.6 mm | 11,080 x 54 x 1.6 mm | |

| Rest piece length in auto operation | 40 mm | ||

| Total power | 15 kW | ||

| Saw Feed | servo-feed via pinion gear | ||

| Material feed | ball screw | ||

| Material clamping | hydraulic | ||

| Saw blade cleaning | electrically driven chip brush | ||

| Dimensions & Weight | VPS60-160A | VPS60-200A |

VPS60-220A |

| Length | 10,900 mm | 11,700 mm | |

| Width | 3,600 mm | ||

| Height | 4,220 mm | ||

| Weight | 17,000 kg | 19,000 kg | 19,000 kg |

| Material Support Height | 1,650 mm | ||

Harga Behringer Automatic Plate Bandsaw Machine VPS Series

Silahkan isi formulir di bawah ini untuk mendapatkan harga terbaik dari tim kami.