[Updated 17 June 2021]

The unified thread gauge is a screw thread gauging system which follows the Unified Thread Standard (UTS). It is a standard thread form and series which comes with the allowances, tolerances, and designations for screw threads commonly used in the United States and Canada. The unified thread gauging system comprises a list of screw thread characteristics that must be inspected to establish the dimensional acceptability of the screw threads on a threaded product and the gauge used when inspecting those characteristics.

The UTS is the main standard for bolts, nuts, and a wide variety of other threaded fasteners used in these countries. The basic profile of UTS threads is similar to that of the ISO metric screw thread. It has the same 60° profile as the ISO metric screw thread, but the characteristic dimensions of each UTS thread (outer diameter and pitch) were chosen as an inch fraction rather than a metric value. The UTS is currently controlled by ASME/ANSI in the United States.

Types of Unified Threads:

- UN – Unified Fixed Pitch

Commonly used with 4, 6, 8, 12, 16, 20, 28 & 32 standard thread per inch.

- UNC – Unified Coarse

The most commonly used thread type for fasteners, General purpose inch gauging, lower tensile strength materials. Due to the inherent coarse pitch, the threads are deeper than UNF and easier to install without cross threading.

- UNF – Unified Fine

Common use: External thread stronger in tension than coarse thread due to the lesser thread depth compared to UNC and it has finder tension adjustment and tighter tolerance. It is commonly used in the aerospace industry.

- UNEF – Unified Extra Fine

Common use: Finer thread compared to UNF and it is used for very special applications such as tapped in thin wall material and tapped holes material.

- UNJC & UNJF –

Commonly used: Similar thread form with UNC and UNC except the outer thread has larger root radius than UNC or UNF thread. Therefore, larger tensile area and smaller stress concentration.

TPI (Thread per Inch)

In unified threads, the thread pitch measurement refers to the count of number of threads per inch along the length of a thread. Generally, thread per inch is used in Unified thread while thread pitch is used in Metric thread.

Unified Thread System

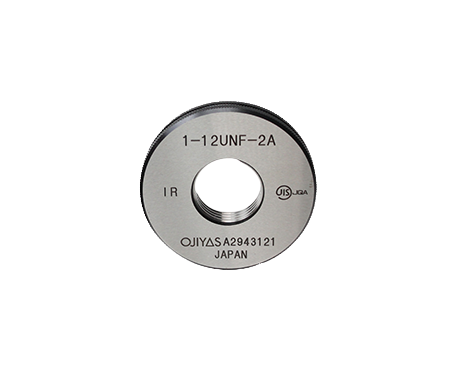

The classes for Unified Thread are designated by letter ‘A’ & ‘B’. Thread Plug Gauge is ‘B’ while Thread Ring Gauge is ‘A’. Therefore tolerance classes 1A, 2A and 3A apply to Thread Ring Gauge and Tolerance classes 1B, 2B and 3B apply for internal threads. Most commonly used are the Class 2A and 2B.

Definitions:

For example: Thread Ring Gauge ¾-10 UNC 2A

¾ = Outside diameter

10 = Thread per Inch

UNC = Thread series

2A = Class Tolerance for Thread Ring Gauge

|

|

|

|

| UNC Thread Plug Gauge | UNC Thread Ring Gauge | UNF Thread Plug Gauge | UNF Thread Ring Gauge |

UNC vs UNF

- UNC Thread are faster and easier for assembly of component with less likely of cross threading

- UNF Thread has higher strength in tension due to the larger tensile stress area compare to UNC

- UNF Thread has shorter threat depth which is suitable for threading in thinner wall

- UNC Thread are less likely to strip when fasten into lower strength material

- UNC Thread has better fatigue resistance due to the less concentration of stress at thread root radius

- UNF Thread allow more precise adjustment

- UNF Thread has limited length of engagement therefore it provide greater strength

- UNF Thread are easier to tap in harder material

LFC is the authorized distributor for Ojiyas in Singapore and Indonesia. Contact us if you wish to discuss about your gauging applications.

You can also click here to view the complete products for Ojiya Seiki Co., Ltd.